Sometime back in 2020, a friend of mine “Farrel O’shea” suggested that it would be a good idea to put a Jet on to one of his Paddle Boards. Actually I don’t think he ever said it was a good idea, but that has never stopped a project before..

The engine that was chosen for the project was from an Aero L-29 Delfín jet trainer aircraft as I had a couple of these waiting to be used in a project. There were serious questions about the size and weight of one one of these on a paddle board, so over a year or so, balance and float tests were conducted and it was decided that it should be OK and not instantly want to go turtle when floated.

Type: Single shaft centrifugal flow turbojet engine

Length: 2,067 mm

Diameter: 896 mm (max. width) × 928 mm (max. height)

Dry weight: 330 kg

Compressor: Single-stage centrifugal

Combustors: 7 straight-flow combustion chambers

Turbine: Single-stage axial-flow with 61 blades

Maximum thrust: 8.75 kN (1,962 lbf)

Air mass flow: 19.6 kg/s (37.25 lb/s)

The engine is made by Walter/ Motorlet and is designated as a M701C-500 Turbo Jet Engine. I used my son Fred to gauge the approximate position of the engine and to to see how low I could get the engines center of gravity as the engine is quite heavy at 330KG’s.

It also occurred to me that the final rig would need a launching trolley, a basic arrangement would be fine.

The paddle board is made by O’Shea and is the Inflatable “Super Jumbo” model, the type of board you might use for team building etc, ideal for this job at hand. www.osheasurf.com/

I have also elected to to put supports and guide rails on to the trailer to ease the launch and recovery of the paddle board when in use, I then coated it with a layer of red oxide paint to help protect against the sea water.

The next job was to make a light weight running frame, I used 25mm square box for this and gave it an undercoat layer of red oxide.

I had concerns about the heat generated from the engine and also the weight distribution of the the frame might damage the board. This will be rectified by fitting a load spacer sheet of marine ply on to the under side of the frame to separate the board and frame. No good just leaving it untreated, two layers of primer were added to protect it.

And actually, while I am at it, I may as well copy the colour scheme of the paddle board that the ply will be covering.

Yep, I am happy with that, the colours are not exact, but it is more than good enough.

And then the frame received a coat of a paint to, all colour coordinated which I think is nice.

The M701 mounted on to the frame ready to be fitted on top of the board. It’s worth noting that that I have decided not to attach a propelling nozzle to the exhaust, I expect lower initial thrust levels when starting off will be beneficial.

Also a Concorde Olympus 593 in the back ground just for effect 🙂

Flotation test, better than I imagined to be honest.

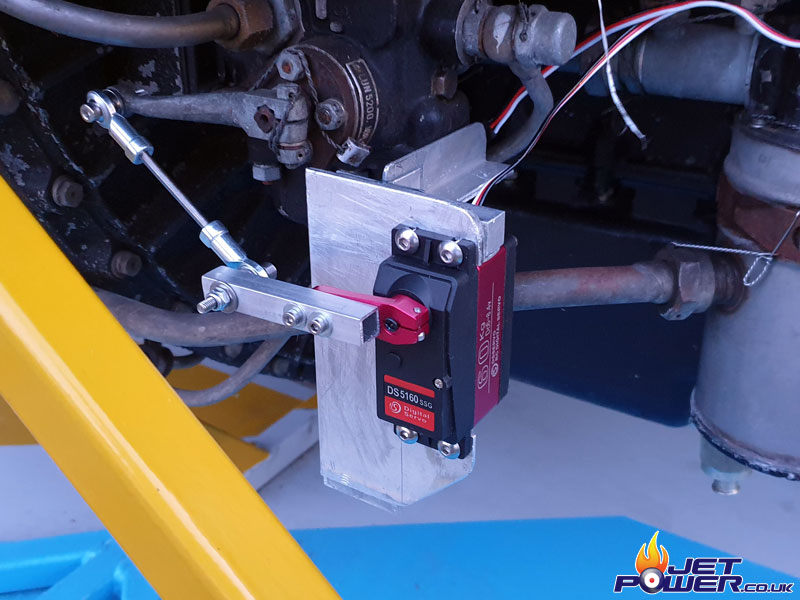

Should the crew of the paddle board ( Farrel & Adam ) fall off, there would be no way to stop the engine, so I devised a remote control system that I could control from a chase boat or maybe even the shore. Pictured below is the throttle arrangement, I made use of servo’s that were rated at 60KG, just to be safe.

Should the receiver for some reason loose communication with the transmitter the receiver will automatically take the Throttle & HP Fuel Servo’s to their start positions i.e. off.

And this shows the remote control HP Fuel Cock Valve & Servo.

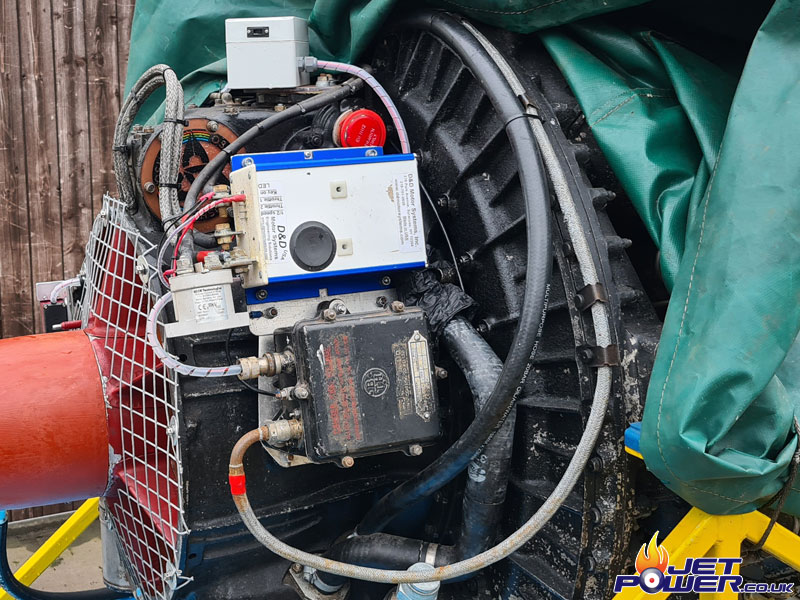

From the top of the engine:

Grey box that houses the radio receiver and RX Battery

The blue & white box gives a soft start to the starter motor

To the left of the start box is the starter isolating contactor.

The black box at the bottom is the HEIU.

The starter and the high energy ignition unit (HEIU) are also controlled remotely with a receiver failsafe programmed in, although you can not really tell that from the video.

And last but not least is the custom fuel tank, ready to take approximately 45 Litres of Jet A1. The original fuel line would have been around 1″ in diameter, instead I have fitted a 5/8″ fuel line, which will act as a safety device by restricting fuel flow should the engines fuel control unit ( FCU ) fail and want to go to 100% power which is something I do not want to happen.

A considerable amount of time was taken to make sure the engine would run correctly and as expected, lots of fuel and tweaking of the radio gear.

Before the M701 was taken to the coast, I had one more run at home.

My mate Justin took this close up video of the M701C starting from behind. Filmed mainly in slow motion for effect.

I never laughed so hard in my life, it seems jet engines are warm at the exhaust end 🙂 Great video though Justin.

Static Thrust Test to determine how many folk will be needed to hold the paddle board when the engine is started.

So after about a months solid work getting the engine running and making the required hardware as well as some important testing, a suitable day was chosen and we all headed out to the beach 🙂

And there we have it. I hope you enjoy the video.