Home of the ONLY Privately Owned Road Legal Electric Gas Turbine Powered Car, and that’s a fact. This one is a Biggy!

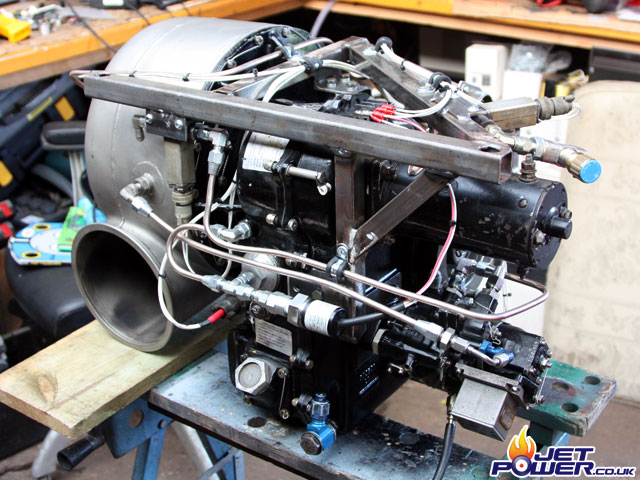

The GTP70 shaft drive (6000rpm) gas turbine engine is my current choice for the power plant of this project. There are downsides, it cannot be throttled to a point where it can be used to reliably control the speed of a vehicle, on the positive though, the sound levels are below 99dBA, a requirement to be allowed on UK roads.

To confirm the sound levels, a meter was placed 50cm and 45 degrees from the exhaust, in this particular case the engine was run up to 100%, although no load was present, you can see 93.2 dBA was recorded which is good news, with a silencer of sorts this could be reduced.

Next I ran the engine at 60% to see if the levels had been reduced, although slightly less at 91.4 dBA it became obvious in this test at least that engine speed had a minimal impact on volume.

In the garage from days long ago, I found the original silencer from a GTP30, a similar but substantially smaller engine and decided it was worth seeing if this made a difference to the levels, a drop of about 0.2 dBA was recorded, a small amount, but none the less it was quieter.

My second option for a power plant was a Rover 1S60 generator set, I went to see Ian and we ran it up whilst checking the sound level, slightly higher at startup (96.8dBA), but it soon settled back to 89dBA once running.

I then made some measurements, around this time I had just purchased my donor car and it soon became obvious that the 1S60 wasn’t going to fit, a shame as I would like to have had a Rover engine in a Rover car.

The third option was a GTP30, measurements were made and with a bit of work to the car it would fit, which was a relief, the only downside is that the power output would now have to be 25kVA, still enough though, just.

The max dBA level recorded of the GTP30 was 91.8dBA, not a lot quieter that it’s big brother the GTP70, but has now become the final choice of engine.

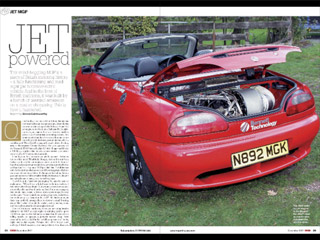

The donor car for this project is going to be a Rover MG-F convertible mid-engine sports car.

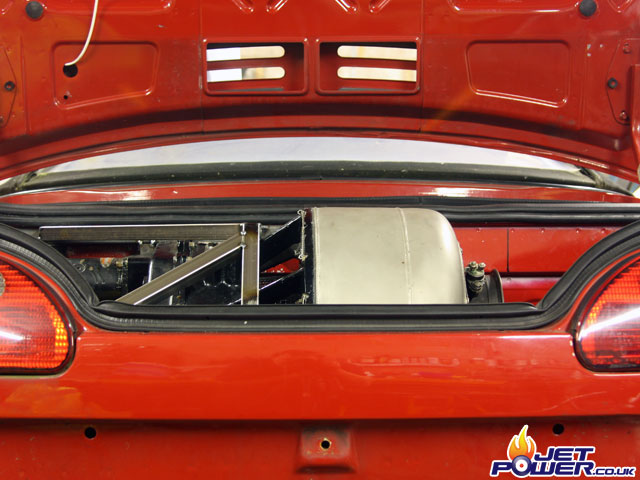

The plan at the moment is to mount the GT in the luggage compartment and have the silencer, batteries, differential and control electronics in the original engine bay.

To access the original engine for maintenance you have to fold the hood forwards and undo a few bolts that secure the rear parcel shelf.

I guess that there was a bolt that didn’t want to come undone in this picture.

As I don’t have a garage ramp to lift the car, we used a couple of straps attached to my engine crane and then placed them through drainage holes in the luggage compartment to lift the car high enough to drop the engine out from underneath.

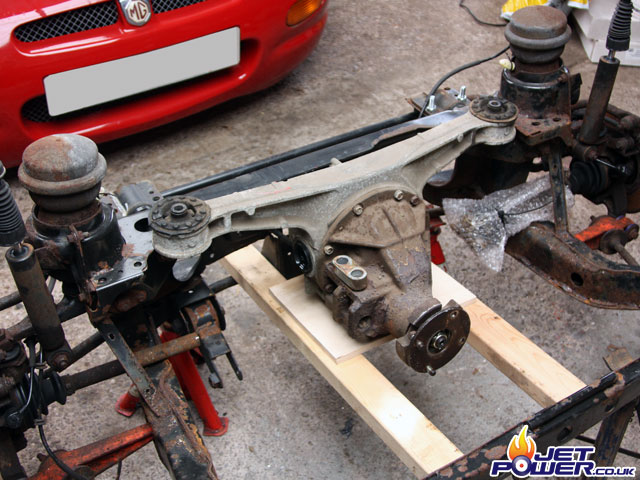

Sub frame removed to which the engine is still attached, time consuming, but at least all is going to plan.

Mymate Will Parry disconnecting the coolant and cab heating pipes, I would have struggled without his helping hand.

Removing the engine and gearbox from the sub frame.

Engine out. 🙂

Sub frame power washed and cleaned, the only downside of the MGF is the hydragas suspension, it works really well, but has to recharged everytime you remove the subframe.

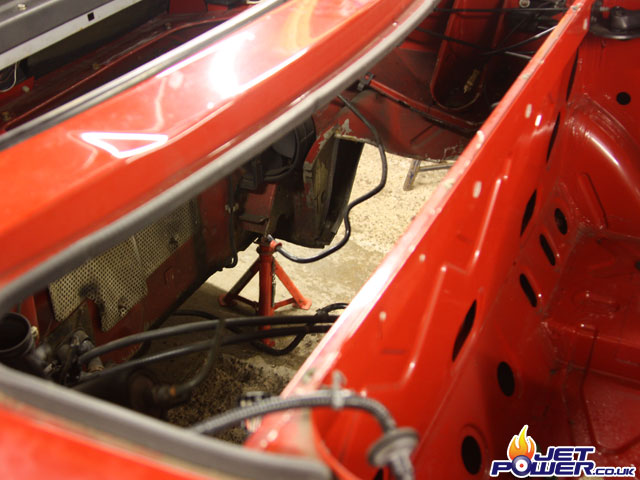

A view of the engine bay from the front.

A view of the engine bay from the rear looking down the vent slot, this is where the silencer will be mounted.

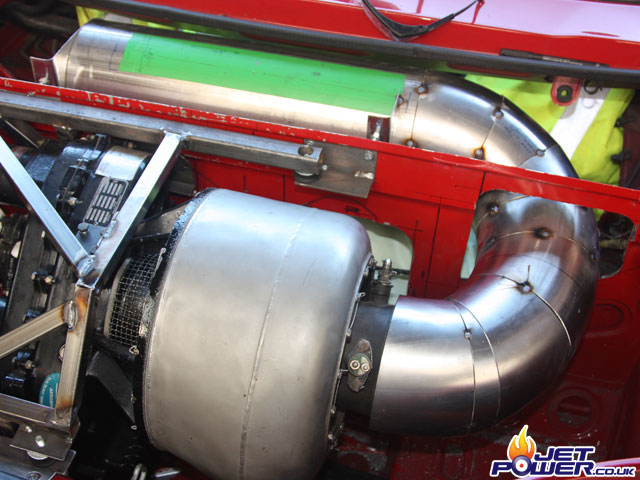

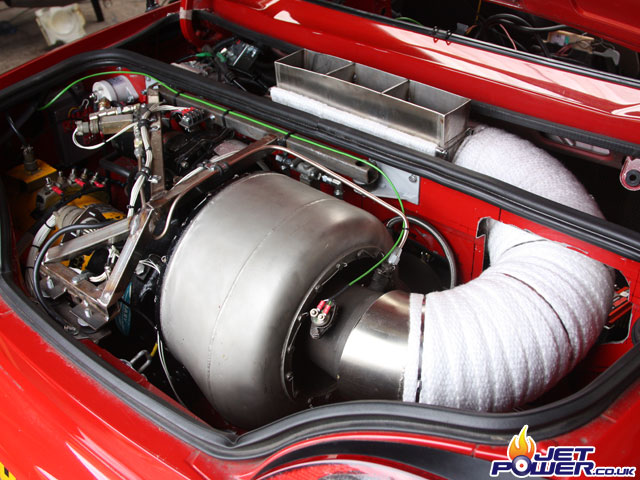

The first attempt to see if the GTP30 was going to fit. The image shows the engine before modifications were made to a couple of panels, hence the engine is still a little high.

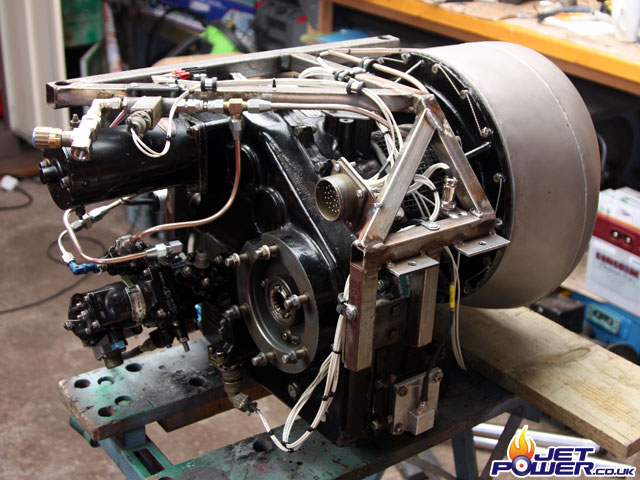

A supporting frame was made from scratch and utilises four shock mounts to reduce any knocks to the engine, there is a little more to be done here, but essentially the frame is now finished.

Another view of the GTP30 mounted in to it’s new frame.

Another view of the GTP30 mounted in to it’s new frame.

This picture shows the engine installation from the rear of the car and you can see that the boot will just about close without touching the plenum.

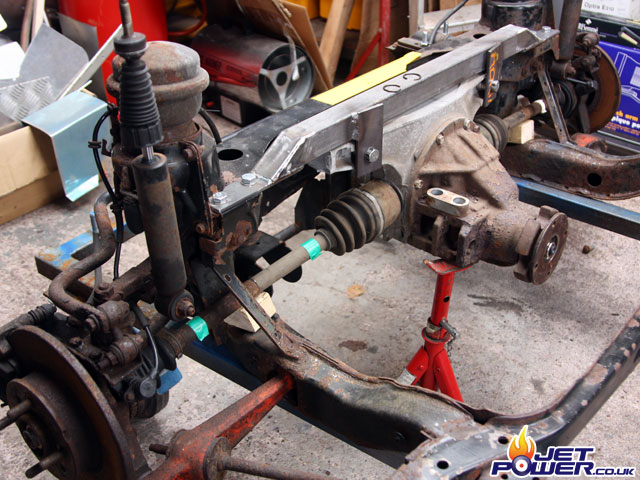

Now to start the transmission, a few phone calls were made to various people, all of whom have offered different solutions on how the diff and motor mounts could be attached. I decided that a MX5 differential coupled to four 72 volt DC PM motors using chain & sprockets is going to offer the best solution, the mounting has currently still not been decided upon.

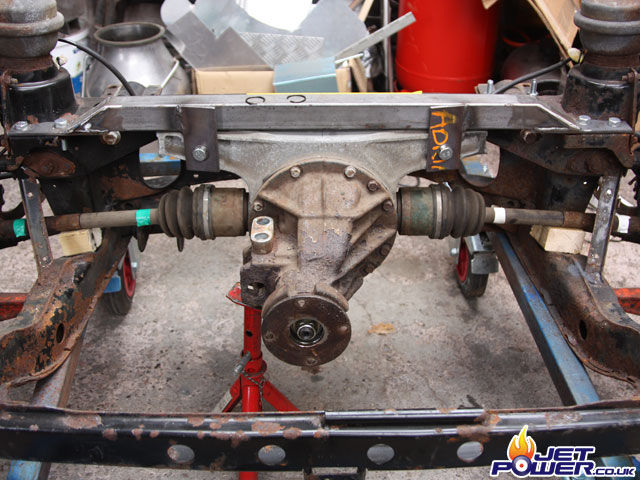

The differential situated in place, this is one of those occasions where I pop in to the workshop and just stare at the sub frame pondering different solutions, so far I must have been looking at this for two to three hours without deciding the best route to take.

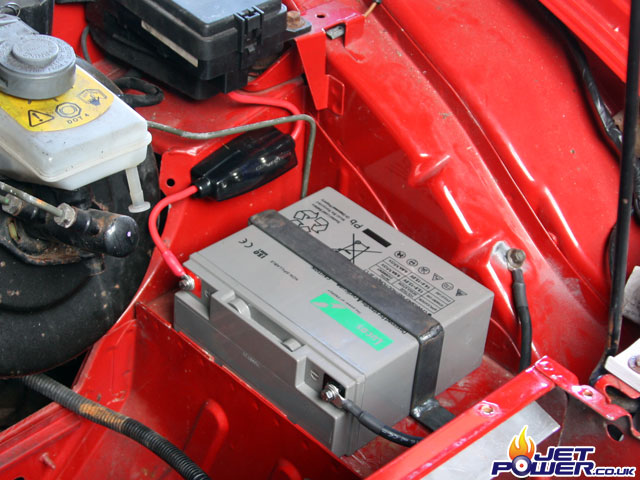

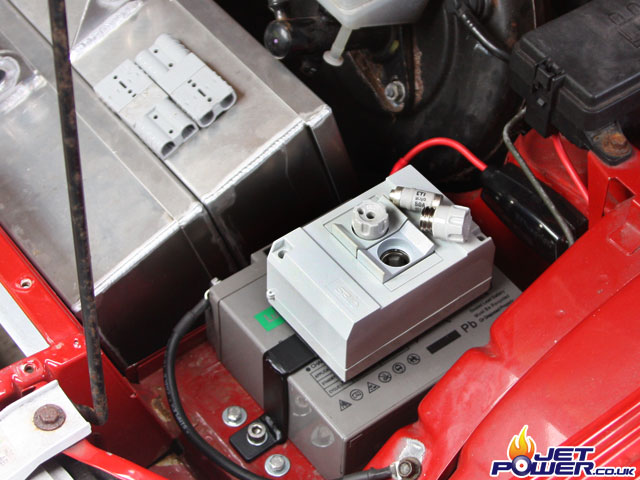

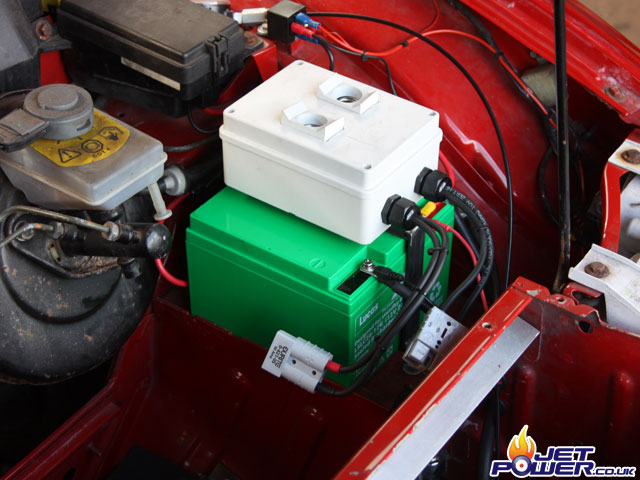

The original 12 volt battery has now been disposed of and replaced by a 22Ah cyclic battery, obviously there is no longer an engine for it to start, but it will have to deal with additions like a vacuum pump for the brakes and possibly an electric demister for the windscreen, I have added an extra fuse inline for extra protection.

To act as a buffer for the drive motors and to significantly aid the acceleration from standstill I am going to use 50 4.5Ah cyclic battery’s in the configuration of 2 X 25, thus 2 strings of 300 volts.

For storing the batteries I have had two aluminium style ‘brief cases’ fabricated, designed for strength due to the weight, they will each contain 24 batteries, the 25th battery will be mounted somewhere near the cases under the bonnet.

This image shows the battery’s in place, a 3mm layer of Teflon will insulate the battery terminals from the lid.

One complete 288volt battery pack.

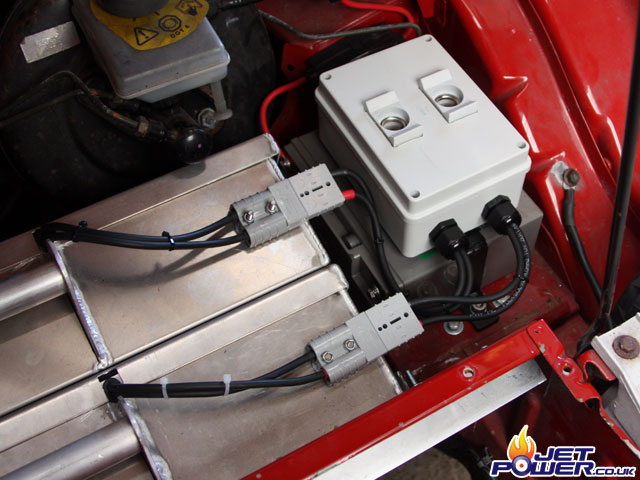

This shows the battery packs in place, I have yet to devise a way of safely securing them to the car, also the anderson style connectors have yet to be attached to the cases.

The MX5 Differential has now had it’s rubber mounting lugs cut off and two M12 holes drilled in to the Tee part of the Diff, two 22mm steel spacers are used to space the Diff from the mounting supports which are welded on to 40mm square box, the box section is then bolted to the sub frame using the original engine mounting holes.

Also the drive shafts from the MX5 and the MGF have now been cut to size and a suitable joining collar will be made to join the two together.

I have also started to strip, wire brush and replace worn joints and corroded nuts and bolts, at this stage I have not bothered to give them a lick of paint as next winter tinker time I intend to replace the front and rear sub frames with MGTF sub frames if possible that utilise Coil rather than Hydragas suspension.

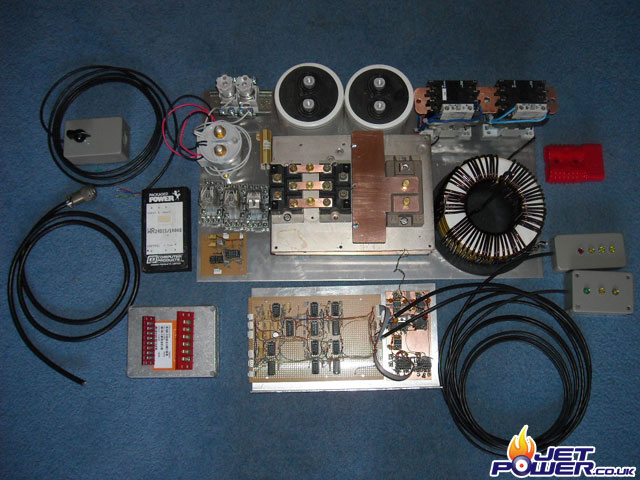

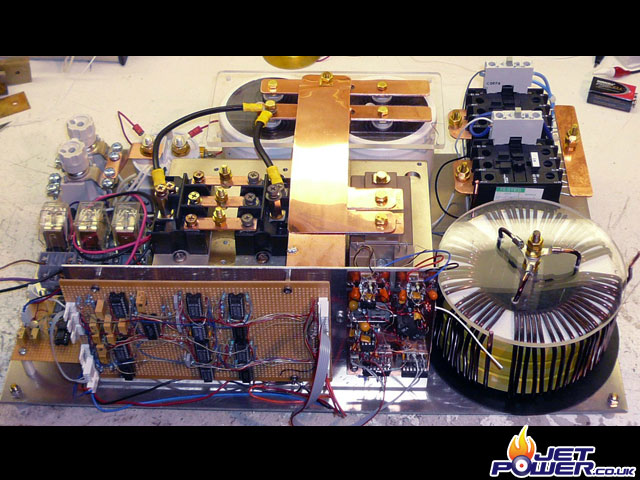

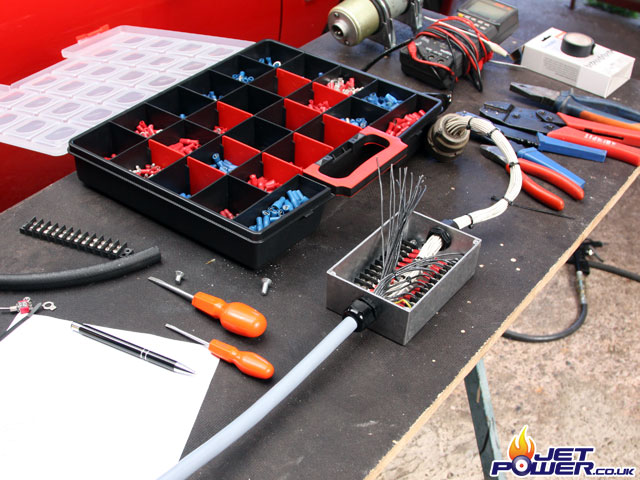

Meanwhile Paul has been busy making the electronic speed controller and charging circuits, I have not physically seen the assembly yet, but I understand that an area of about one square foot will be required to mount the hardwear.

The start of the control electronics, I expect I owe Paul half a shandy for this, possibly a pint when completed.

The controller electronics are coming along nicely, thanks to Paul & Ian.

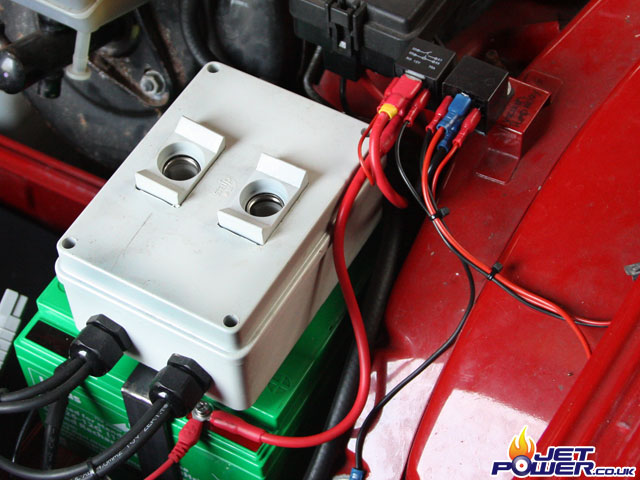

A pair of high voltage DC fuses installed.

One of the issues that I will have with this MkI MGF is that the speedo gauge is mechanical and as the original gearbox, where the drive came from is no longer part of the car I have decided to replace the clocks with ones from a MGTF that are electronic.

Yet another nice word with Paul and hopefully he will be able to make me a pulse circuit that will drive the speedo from the differential, at this point I may also integrate the on board warning indicators with those of the custom computer control system.

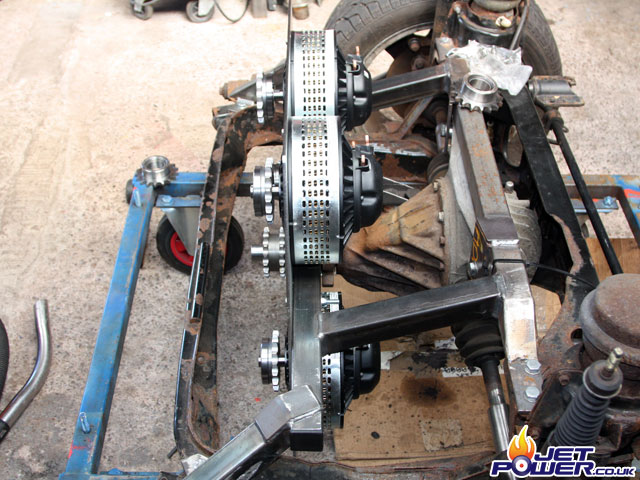

The sub frame and running gear setup for testing the speed controller at Paul’s house.

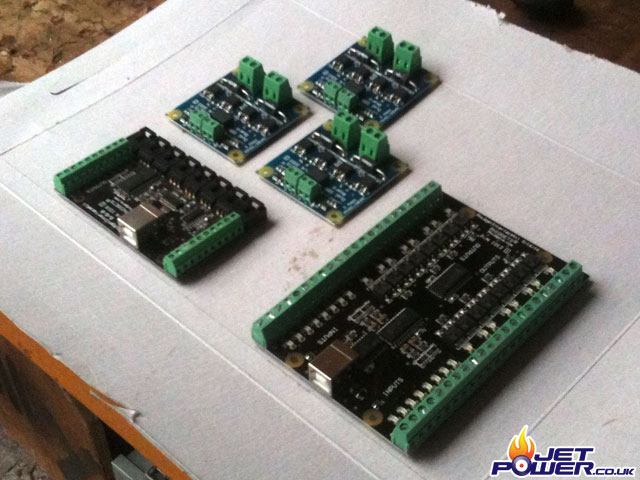

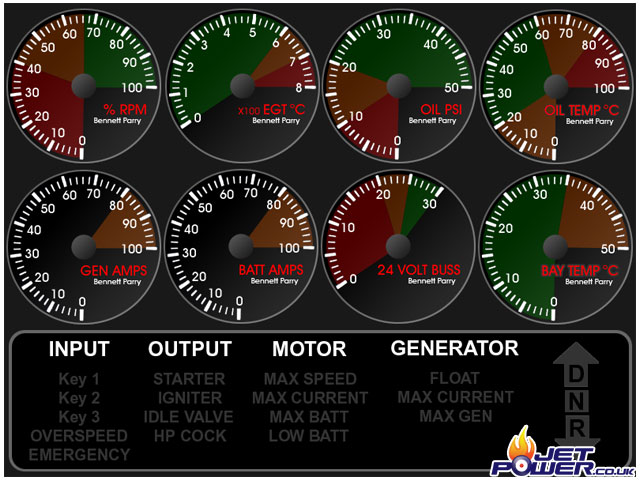

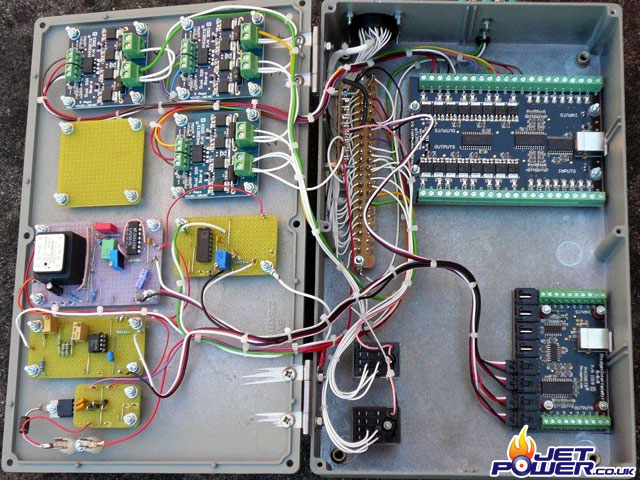

The Phidget boards that will interface the engine to the computer thus showing live data at the display.

The finished car will have an onboard Windows 7 computer that will control all aspects of the engine, battery voltages and currents, I have decided to use Phidget USB boards for the interface and to make programming easier I have made a control box that will simulate all of the engines parameters.

Steve working merrily on the Visual Basic program that will be the brain of the engine.

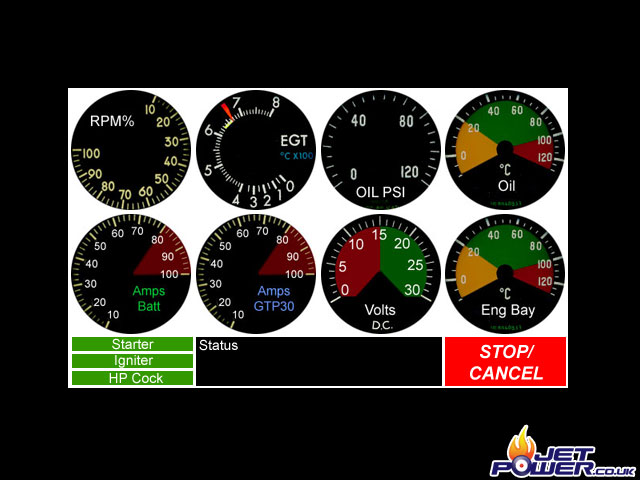

Good progress on the gas turbine management program.

Pictured is the ‘In Dash’ usb touch screen monitor that will provide the audio & visual indications as to the state of the GTP30 at any point.

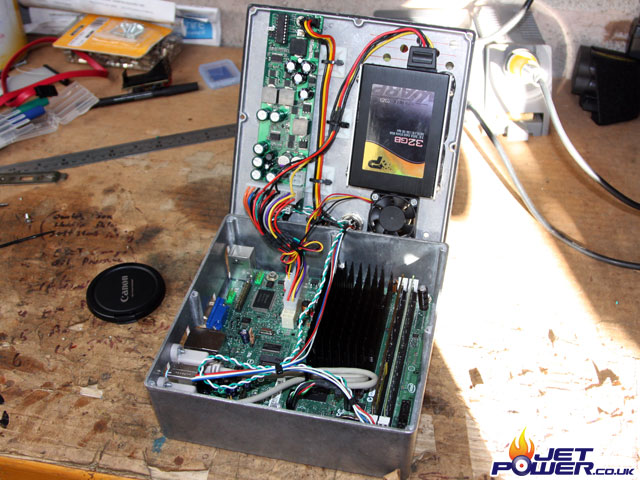

The start of my custom mini computer case, 2mm aluminium is being used as the support for the mainboard, this has the been tapped in the appropriate places with a 6.32 thread to accept spacers that will fix the board and PSU in to place.

I am currently building the computer based on a Dual-Core Mini-ITX mainboard using a 32GB ‘SSD’ Solid State Drive, coupled with 2GB of DDR2 RAM. Using a computer is handy as all of the telemetry can be easily recorded for future analysis.

How the layout of the GUI is currently looking.

In an attempt to try and reduce the size and weight of components, I am going to utilise this Via Epia PX10000 mainboard, as you can see it is very small, the power supply and hard drive have yet to be added to the computers case increasing it’s volume.

Pico mainboard, PSU and drive all fitted in a quite a small box, not a lot of room left, but there again it’s not needed, so far so good, this will be easy to fit in to a hidden place in the car.

Finished box with an added air vent that allows the processor fan to make use of cool air. Now the bad part, the mainboard doesn’t properly support windows 7-32 bit, which is a problem as the software has actually been written for the windows 7 platform, time to make yet another computer.

Computer version 3, back to the Mini-ITX mainboard which is a very tight fit in to a 17x17cm alloy case. The PSU and SSD have been mounted on to the case lid and a fan added to extract any warm air.

So far I have carried out quite a few hours of testing with this particular computer and it has proved to be very stable and work extremely well, there was a point where I thought I was going to have to use conventional aircraft gauges and bin the glass cockpit, my faith is now restored.

I am now going to make use of a built in 7″ wide screen monitor rather than one that pops in and out as the my original screen has now failed. For the drive power consumption we are toying with using level meters rather than gauges, this seems to work best with peripheral vision.

Our very scientific testing and development bench.

This now pretty much concludes the software and hardware phase of the project, its now down to Ian to manufacture some clever electronics that will convert RPM and EGT etc to 0 to 5 volts so that the Phidget boards can operate correctly.

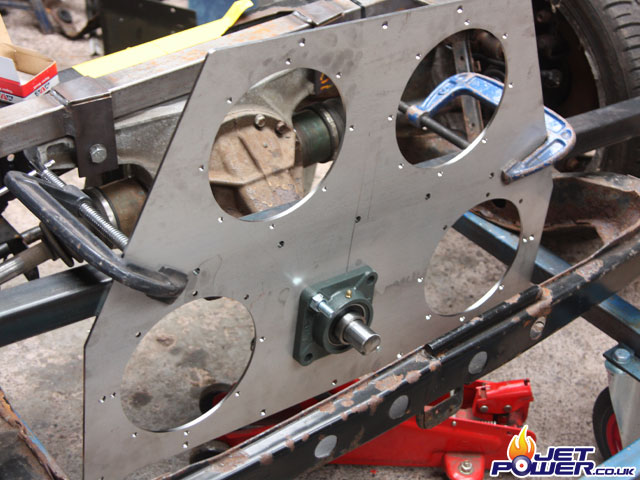

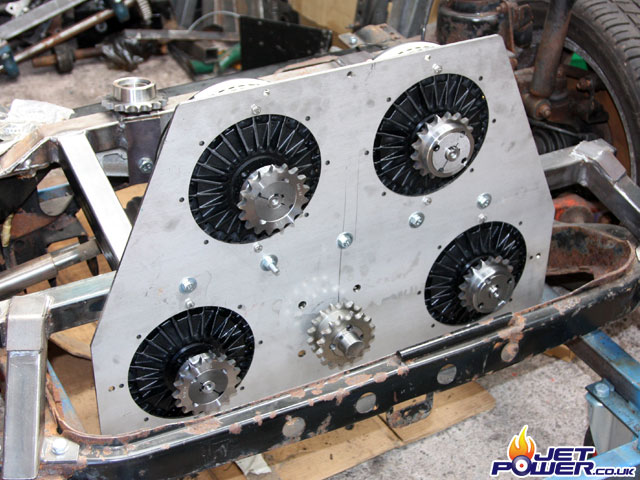

Finally arrived is the laser cut stainless steel plate that the four electric motors will mount to, the hole in the centre is where the differential drive sprocket will be protruding.

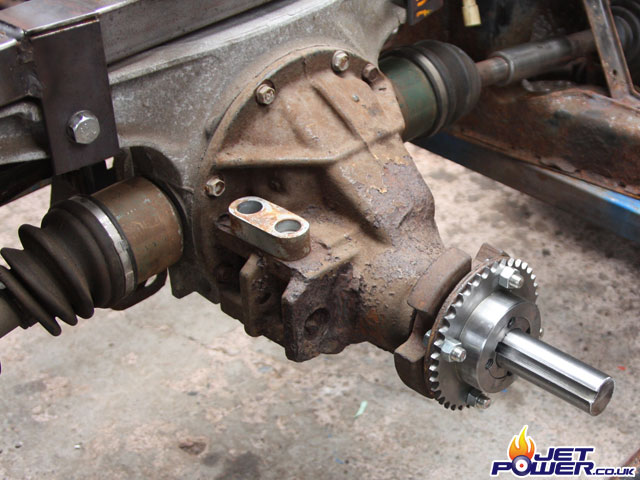

The solution I settled on for the differential drive was to utilise a 38T 3/8 pitch taper lock sprocket, holes were carefully drilled in to the sprocket to match the holes of the diff and bolted , then a 30mm shaft with an 8mm key will lock them together. A bonus spin off of the sprocket is that I now also have a 38T pulse take off to monitor the diff rpm.

Not quite ready for the duplex sprocket yet, but you get the idea of how its going to work.

The pillar block bearing is only mounted for support bracket alignment purposes, once the motor plate is secured, the bearing will be removed, allowing the duplex sprocket to fit fairly flush to the plate and thus reducing leverage on the shaft.

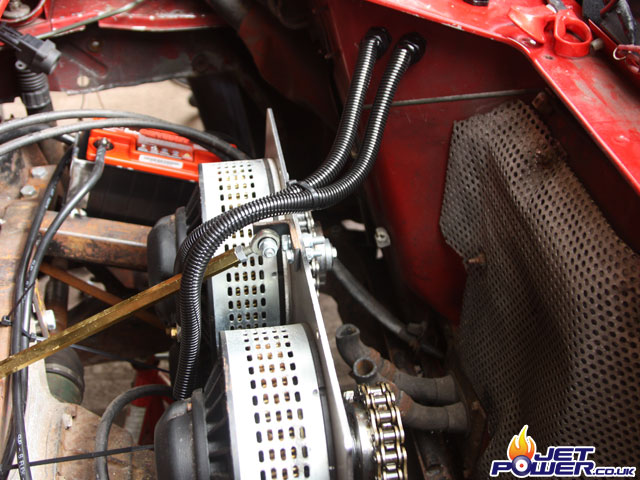

Coming together nicely, the electric motor frame will attach to the sub frames original engine securing points.

Bolted down, time to remove the pillar block bearing.

Differential torque bar fabricated and fixed in to place.

And now with the bearing removed the shaft stays in exactly the same place.

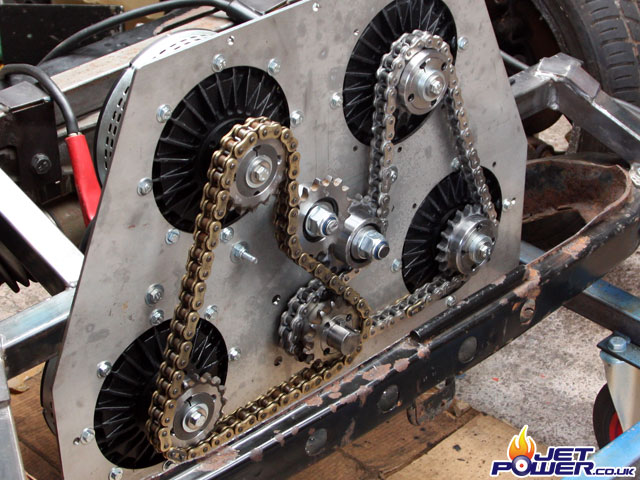

Start of one of the idler/ chain tensioner assembly’s, the plan is to make a top hat style eccentric insert for the bearing, two will be required.

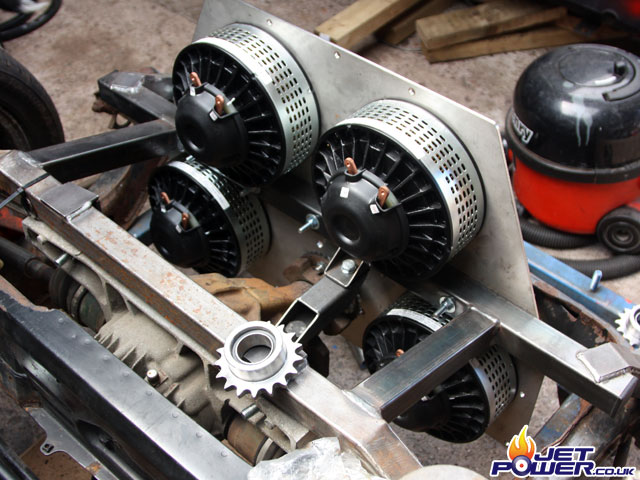

Horayyy !! The motors have arrived.

The power plant for the car consists of four Lynch D135 permanent magnet DC electric motors, quite pricey but the best PM Motors you can buy.

Front facing view of the motors secured in to place, 6mm spacers have yet to be laser cut for the motors on the right hand side to allow the chain and sprockets to be as close to the mounting plate as possible.

Side profile, I am using taper lock 17 tooth sprockets on the motors and a single 16 tooth duplex sprocket on the diff drive shaft.

Pictured at the bottom of the image is the start of one of the idler sprockets. I’ve waited a long time to get this far, hopefully progress will now speed up.

Eccentric inserts have now been made and are ready to be fitted to the motor mounting plate.

Idler Sprocket/ Chain Tensioners fitted and chain lengths finalised and joined.

The mounting spacers for the two right hand side motors, laser cut and ready to be attached.

We have to remove the console to gain access to the centre tunnel as there are a few bits and pieces that were either no longer required or need to be installed.

The first part to be removed was the gear lever assembly, to my surprise there is a huge counter weight on the lower end of the lever, no wonder the gear change had a smooth action.

Removing the gear lever leaves a space that hopefully the computer will fit in to, it’s going to be a bit of a tight fit, the next job will be to try it out.

The clutch pedal was next to be removed, I thought this was going to be a pain to do but a slip of a clip and it was off, oh and have a helping hand made it easier to!

The clutch master cylinder mounts directly above the clutch pedal in the bonnet area of the car, this was also a doddle to remove, the copper clutch line to the rear of the car was then removed as well as the original battery power cable.

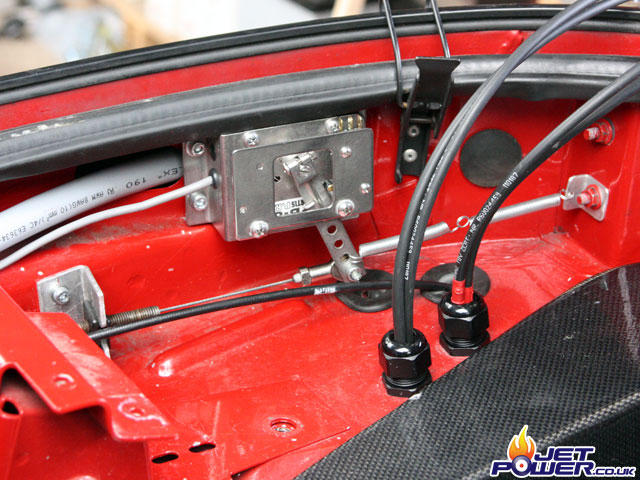

I have made a new locking plate, this is located inside the engine bay and everything that passes from the centre tunnel to the engine bay will go through this plate, the slots shown are for the handbrake cables, a hole is yet to be made for the electronic control wiring on the RH side.

A template was made from a cornflakes packet to the profile of the console insert (originally plastic), this was then used to make a aluminium copy and the curves were bent using guesswork and a large round bar.

Then the monitor screen hole was cut out as well as the slot for access to the temperature controls. The electric windows, hazard and fog light switch were added after that, the hazard switch was originally below the central air vents, so the wiring to the switch had to be extended by about 12 inch’s.

A clever low temp welding rod was used to attach the securing lip to the aluminium dash panel.

This is the bracket that will hold the TFT Screen in place when mounted inside the dash.

After a browse on the internet I found a company in ‘Burton on Trent’ called ‘The Wheel Specialist’, I dropped the rims of with the main man Alan and two days later, hey presto a nice and tidy refurbed set of wheels, the price was very reasonable to. Thanks to Alan and his chaps for doing a great job in such a short time!

Whilst I was on the subject of the cars look, I also asked ‘The Wheel Specialist’ guys to powder coat some of the chrome parts that made up the exterior appearance of the car, keeping the colour scheme the same as the wheels.

Looking good.

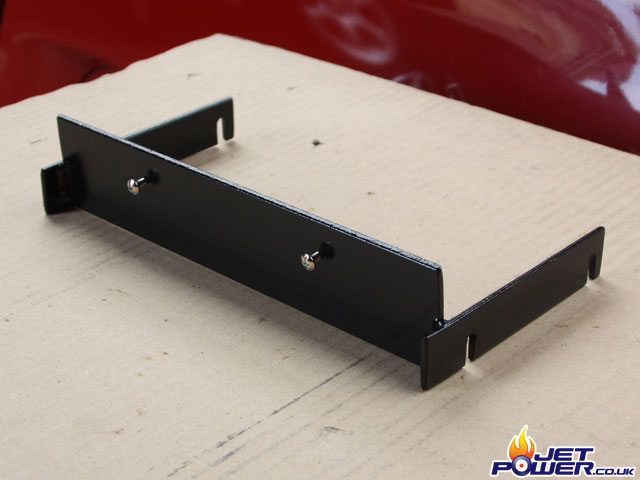

The above picture shows the battery packs lower supporting bracket, made nice and strong to support the weight of 48 12volt battery’s. It also has to be mentioned that the battery packs mount slightly right hand side down, this is to allow clearance of the brake master cylinder & Servo.

I have also decided on a different enclosure to house the DC fuses, a bit more room for the internal wiring, also the quick release connections have now been soldered and attached to the fuse holders.

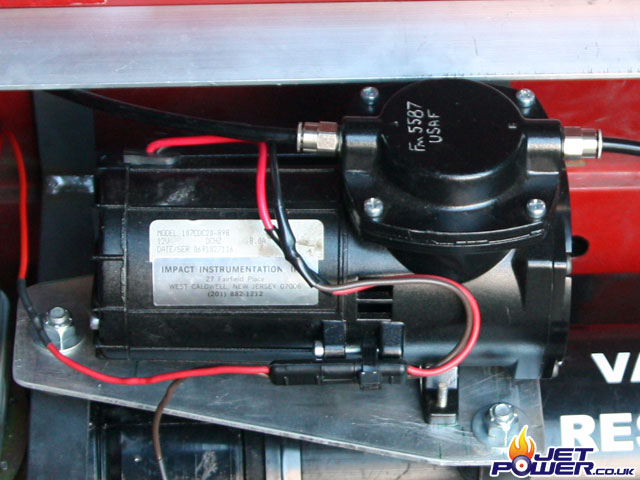

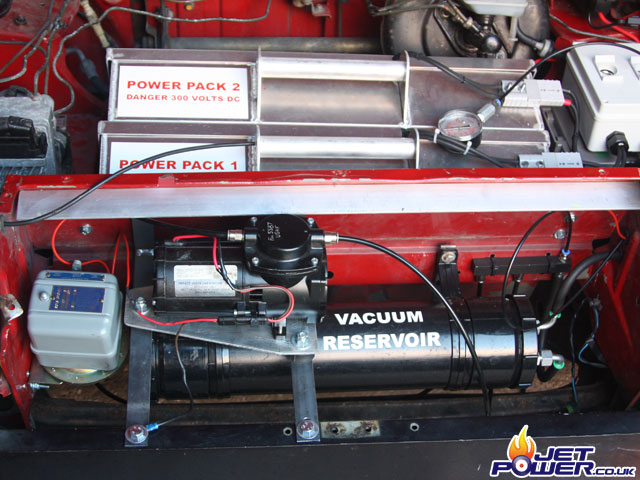

As the car has no conventional engine installed, there is now a lack of a vacuum that will be required to power the brake servo under the bonnet. This is overcome in electric vehicles by adding a vacuum pump, the one I have is ex USAF and conveniently runs on 12 volt dc, the pump becomes energised when the key in the cab is turned to either position 1 or 2 via a power relay.

It is also good practice to have a vacuum reservoir installed to help add to the volume of vacuum available. Mine is made from 110mm drain pipe with removable screw caps either end, bulkhead fittings are inserted in to the end of the reservoir and then connect to a distribution manifold.

To control the vacuum pump a ‘Square D’ adjustable vacuum switch has been added in to the electrical circuit, this switch will activate the pump when the vacuum falls below 14Hg and turn it of when it reaches 18Hg.

Complete brake vacuum installation.

300volt battery pack retaining bracket.

There were some fairly serious scratch’s on the windscreen caused by wiper blades that were never replaced when they wore out, unfortunately for me this means a new windscreen, best to keep on top of these things.

The front of the car used to house the radiator, this of course has been removed and as the vacuum pump and switch are now in its place I thought it would be good practice to blank off the air vent intakes on the faring, helping to protect the vacuum components from bad weather.

This should now conclude the work carried out on the front end of the car.

Motivation on the exhaust fabrication was at a minimum for me, so luckily me ole mate Anton was able to give me a much needed kick up the backside whilst giving me a bit of a hand. The exhaust route is not straight forward to say the least, but it seemed logical to start with some pre-bent 6″ stainless steel pipes.

A small hole that fortunately didn’t interfere with the structural integrity of the car has been cut out to allow the passing of the exhaust tube. I new where the final part of the exhaust was going to be, the trick was routing this to the engine. We cut the stainless pipes in to sections and using a couple of spot welds per join we were able to form a respectable pipe assembly with what I would imagine would allow a fairly smooth gas flow.

The pipe doesn’t actually make contact with the engines exhaust, there is a 3mm gap all the way round, this is required as the engine is shock mounted and the exhaust is not. The next step will be to try to find a 6″ trumpet inlet and this will allow for a small quantity of induced cool air in to the exhaust.

In theory, as long as the final box (silencer) is secured firmly there will be no need to mount or secure the exhaust in the engine compartment.

Profile is looking good so far.

Exhaust removed for final welding and Anton pretending it’s a Tuba I guess.

The boot air vent being opened up to allow a space where the exhaust can protrude.

A small stainless rectangular surround plate might just make the hole look a little less boring.

The exhaust exit slot has now been cut out to an area of 30sq”, thus the rectangular hole is about 2sq” bigger than the pipe diameter, hopefully this will help to reduce the inevitable back pressure caused by transferring from a round exhaust to a square exit.

To direct the flow of gas I have made an internal guide plate, firstly from cardboard, then aluminium and then finally out of 1mm stainless steel, this was made last because of the awkwardness of profiling such a hard metal.

The bends were made by wrapping around various sizes of round tube, this is the final version ready to be welded in to the exhaust pipe.

This picture shows the guide welded in to place and the end which was surplus to requirements has now been cut off and discarded.

I have now started to make the guide plates that will direct the gas flow out of the exhaust to atmosphere, the plasma cutter and grinder were mainly used to get the results required.

This will be the end plate of the exhaust, the lip on the left is where the plate will attach to the bracket fixed on the car.

The gas flow of the exhaust has caused me concern for quite a while now and for an initial test I have made use of a disco smoke machine to gauge the characteristics of the exhaust flow.

The next step was to add some proper pressure behind the gas flow by making use of my DIY Turbine. The P2 pressure was at 1 Bar and pushing on the exhaust could not be felt when placed in the efflux, in fact it seemed to silence slightly as well, so far so good.

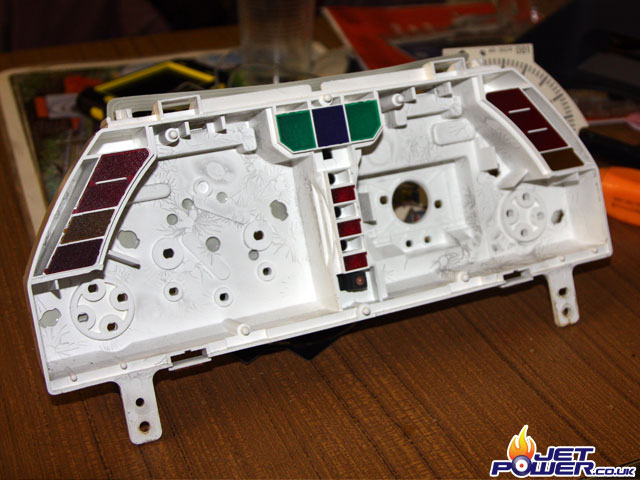

After I had a look at converting the newer electronic clock so that the speedo could be made to work, it soon become apparent that it would be easier to start from scratch as the two clocks were actually quite different in design. I started of by striping down the original speedo and thus put the electronic speedo back on eBay.

Pictured is the main clock assembly stripped down, I have decided to add an electronic kit car type speedo to the right hand side and may add some voltage sensors to a panel yet to be fabricated on the left hand side.

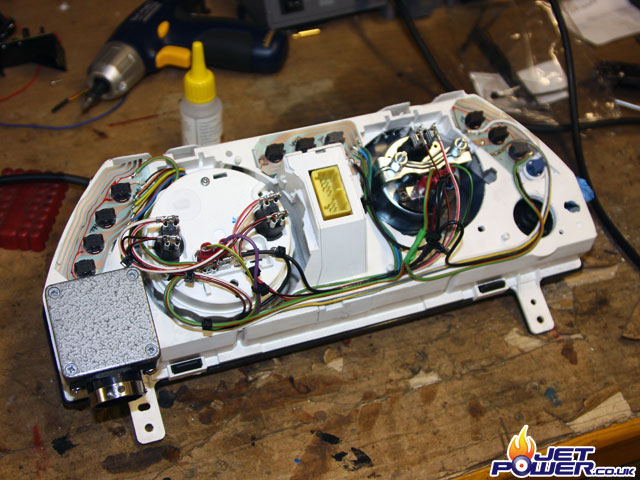

Using tank cutters two large holes were made to allow the fitment of a VDO electronic speedo, fuel level gauge and 12 volt digital meter. The printed circuit was cut down to fit the new layout and allow the continued use of the existing lamps and holders. With some modifications the connections now terminate in a MIL spec multi pole connector.

Fortunately the wiring loom that connects to the dash is removable, this made it easier to replace the crappy printed circuit connectors with a MIL spec plug which then mates with the connector on the clock assembly.

The aluminium plates that mount the speedo and tacho have now been powder coated to a similar colour to the wheels, the original fuel and temperature gauges have been covered in grey vinyl as the base is hard to replicate and also made of plastic.

It’s now time to somehow link the throttle pedal to the electronic speed controller, my solution for this little problem was to purchase a 5k pot assembly with sprung lever and micro switch built in, so not a lot to do really, it will sit in the original engine compartment and be attached to the throttle cable that runs down the side of the car, a handy unit made by Curtis Instruments (Model is PB-8).

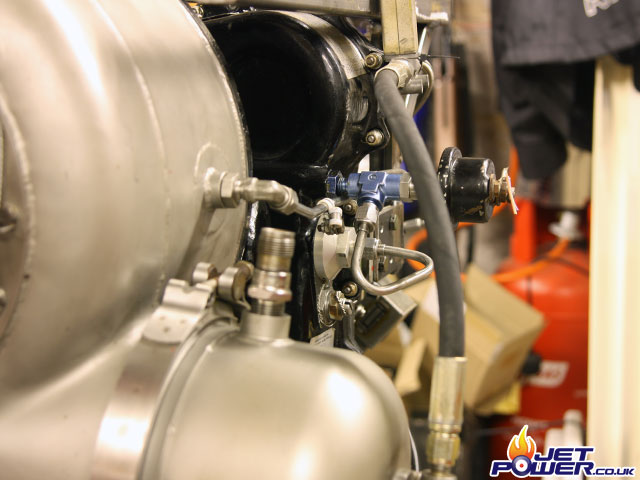

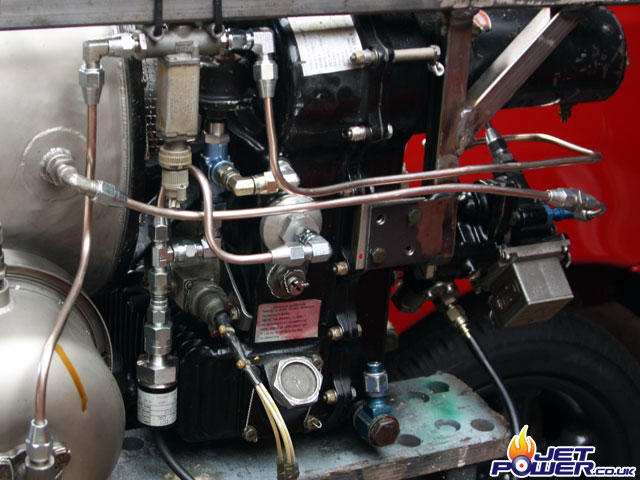

A picture showing the new modified oil and fuel pipe work that has a low profile and allows easier fitment of the engine in to it’s bay.

Another view of the modified pipe work.

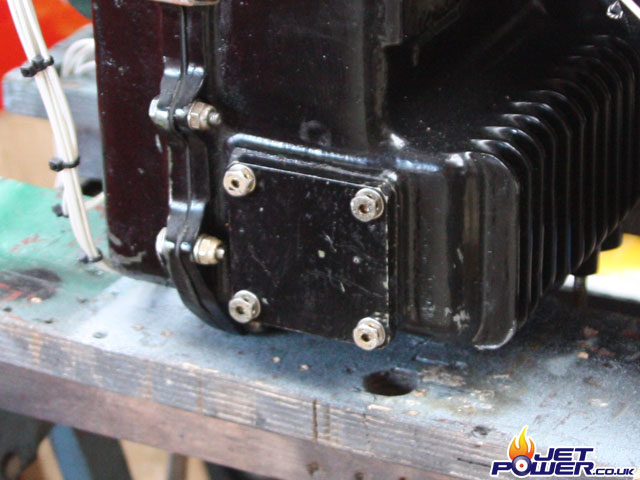

This image shows the oil sump inspection plate, this is where I am going to mount the oil temperature sender, a new plate will have to be fabricated.

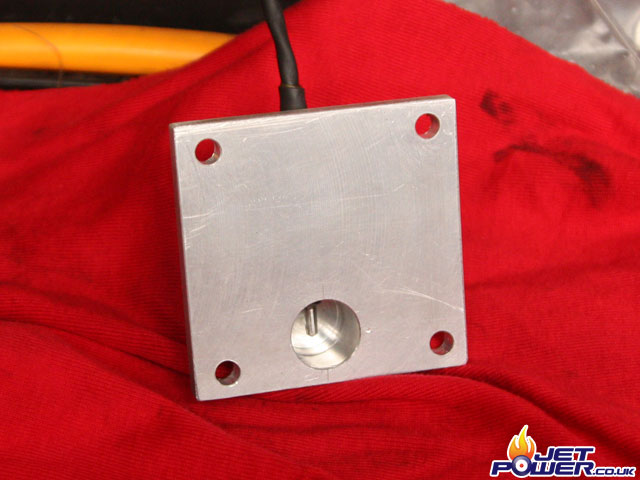

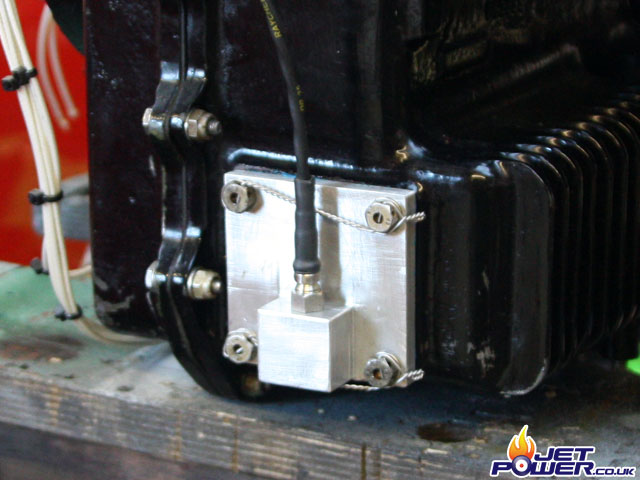

And here it is, a replacement cover that has provision for a temperature sender inside it.

And now mounted on to the engine itself.

OK, found a few issues with the modified pipe work, so now pictured is my mkII version , I feel a lot happier with it now.

The image shows the wiring that connects all of the accessories to a multi pole connector. The connector was salvaged from a EMU12 GPU, a handy find.

Engine now fitted in to it’s bay with modified pipe work and wiring, it looks a lot neater.

The old Fave, Lucas CAV type fuel filter will do the job nicely for the GTP30, additional input and output ports are there if required for future use.

To get the fuel from the tank, I have inserted a 24volt Facet inline fuel pump between the tank and the filter assembly, it’s only rated at 4psi, but it is enough to suck the fuel up from the tank when the fuel level is low. The cars original built in fuel pump, has now been removed and has been marked for use in another project.

To meet with regulations I am going to make use of the existing inertia switch, the Facet pump will be wired in series with this device, should I be unfortunate enough to be in a crash this will stop the power and consequently the fuel being pumped out from the tank.

This die cast aluminium box sit’s just below the rear left hand light cluster, the multipole connector connects to it’s mate on the engine, the box then houses some diodes which will prevent any EMP from the engines solenoids, the multicore cable then will terminate in to the Phidget control box using a QM multipole connector.

The phidget’s (shown right) have been mounted in to a die cast aluminium box. Upper left are the SSR’s (solid state relays) these will drive the Starter Solenoid, Igniter, HP Cock, Idle Valve and Fuel Pump, below these are some clever bits of electronics that Ian has made that will interface the Phidget’s to the engines sensors. The multi pole connector shown is for the outputs of the interface , another connector has yet to be added for the inputs (mainly Paul’s speed controller data).

The 22Ah battery that I was using didn’t seem to cope with the loads placed on it, not surprising really, it was an attempt to save a bit of weight. Now it has been replaced by a slightly larger 26Ah battery, thus a new retaining bracket has been made and the 300volt battery leads will also have to be replaced as they are now to short.

Due to the amount of electronics reliant upon the 12volt battery even when the car is not in use and the subsequent battery drain taking place, I have inserted a 12volt, 70 amp relay (the upper left relay ) in line to isolate the circuit, this is turned on and off from inside the car.

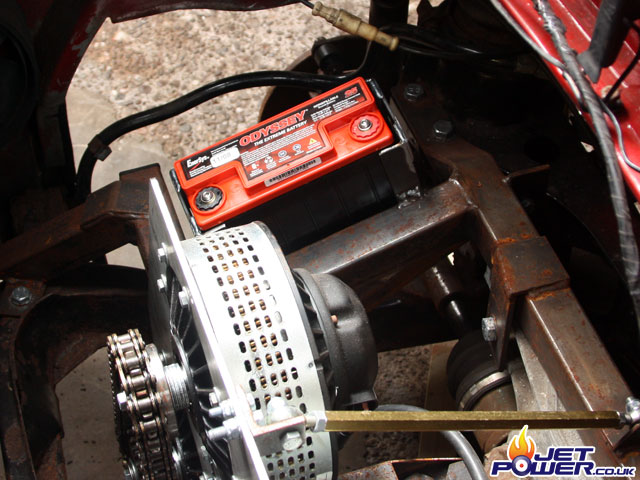

Another purchase from Manbat, two x Odessey battery’s that will be required for the 24volt starting of the GTP30, they will also provide the power required to operate the electronics of the speed controller and anything else 24v that requires power.

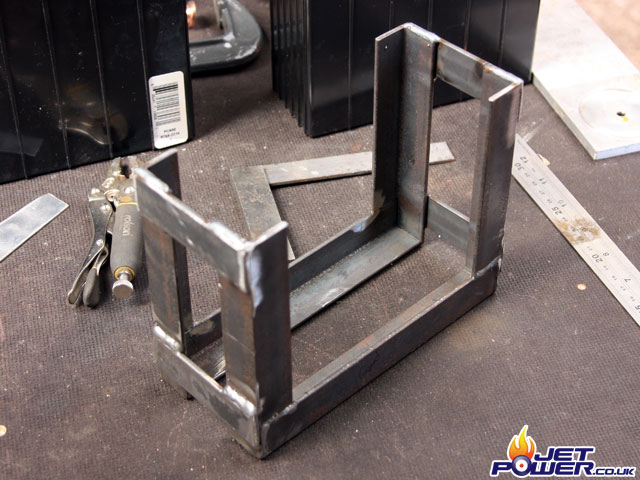

Two battery retaining brackets like the one above will hold the battery’s in place either side of the motor mounting frame.

The bracket welded to the motor frame and battery inserted, they have been mounted here as it’s the lowest possible place available to help keep the COG low.

A view of the battery and frame from the wheel arch.

Today is the day the car goes for an electric test drive, the speed controller was wired up to 12 volts instead of the 300 volt packs just to check that all was in order.

Once paul was happy with the parameters given by the speed controller a slow but steady test was carried out by the workshop, I felt like a bit of a spare part in the drivers seat.

Then off to out local horse stud who kindly gave me permission to use there driveway for testing. As the car is still not road legal it was trailered on a flat bed, a bit of a chore really.

Paul and Will at the controls, time to check the parameters at 10, 20, 30 and 40 MPH, these tests were to clarify the current usage using electric power only as the GTP30 engine has still yet to be wired up to the computer and is not currently functional.

Testing proved to be quite positive, we did take it slow at first, not wanting to blow any electronics up, there was an issue with the drive shaft couplings slipping, this will be easily rectified with the Tig welder.

A close up of the speed controller in action.

A big decision was made today as it was becoming apparent that there was limited space for the control equipment that will be required to run the car. So the soft top option has now been permanently removed to make more space and allow easier access to the speed controller which is going to sit where the soft top used to be when folded. The original engine top cover makes for a good template, the new shelf is being made from 9mm birch plywood. At some point I will buy a removable hard top so it can still be used on damp/ wet days.

The beginnings of the new engine cover, with the recessed sides in place. Because of the gained space in the motor compartment, temperatures become less of an issue, this has been worrying me for sometime, even though it’s a shame to loose the soft top it offers a means to an end.

The wood part of the shelf completed, the box’s in the foreground are the Phidget’s control box and the charger regulator which maintains the 24 and 12 volt batteries in the car, this unit is powered by the alternator on the GTP30.

To stiffen the speed controller shelf, I decided that laminating it with a carbon/ k glass and epoxy laminate would add the most strength whilst looking quite cool, it’s a lot better than just painting or varnishing the ply wood.

Finished shelf ready for the mounting of the control box’s. It has ended costing quite a lot of money to do as I decided to use my favorite epoxy resin SP115, I used to use this in my windsurfing days, very light, very strong and very expensive.

Before the shelf was mounted in to place, the motor power cables were installed running in to the chassis of the car and out of the top panel (just out of view in this photo), this pretty much completes the work needed in this area of the car.

So all was going really well and it was time to run the engine in conjunction with the battery’s and controller. From about an hour before this photo was taken it went bad as you might be able to tell from the expressions on our faces, well at least mine anyway.

After quite a few hours buggering about with the electronics it became apparent that we were suffering from corrupted data transmission along the USB cables causing random events to happen with the Phidget boards, a couple of meaty ferrite cores temporarily allowed us to have a couple of runs of the engine.

Ian adjusting one of the interfaces of the Phidget control box.

The very first run of the engine since being mounted in the car, it was only run at idle and suffered a couple of flame outs, possibly due to the entirely new fuel pipe work that I had made.

The completion of the car doesn’t seem to be far away now and it’s time to install all the components that will make the car work and fingers crossed road legal. Pictured is the curtis throttle pot and lever, connected to the throttle cable, which in turn connects to the accelerator pedal.

For the starter solenoid I have used a Kilovac EV200 unit, very well engineered and has great specs, the box that is just viewable behind it is the generator exciter unit, this is controlled by the speed controller and turned on and off by computer software using the Phidget’s.

The igniter exciter has now been permanently installed just below the exhaust elbow, as close to the igniter plug as we could get.

10mm cable was used to take the power away from the generator to feed the speed controller.

All the engine compartment cabling has now been tidyed up and made shipshape.

Looking as tidy as it has ever been, I just need to wrap some heat resistive tape around the exhaust.

The wiring on the back shelf has been tidyed up and cables cut to their proper length and me mate Will has made a couple of brackets that now secure the Phidget control box and the charger box to the shelf. Two new high quality USB cables were purchased to replace the previous ones and as an added precaution ferrites were clamped on each end of them as well.

A birch plywood shelf has been made to cover the electronics, this will be covered in vinyl and a couple of holes added at some point for ventilation.

I have obtained some silica cloth and wrapped it around the exhaust section to help reduce the internal temperature when the engine is running and boot lid closed. It is rated to 1000 degC and has a peak of 1100 degC, I don’t expect the exhaust to reach anywhere near these temperatures, more like 3-400 degrees, but it’s nice to know it’s well protected.

The exhaust has also had some guide plates welded in at the exit, (thanks to Paul at SDF) these will reliably direct the gas flow upwards and stop any warping that may occur along it’s exit length.

A view of the stainless steel powder coated exhaust plate which has now been fixed in to place using PU adhesive, I think it’s starting to look quite nice now, jobs a goodun.

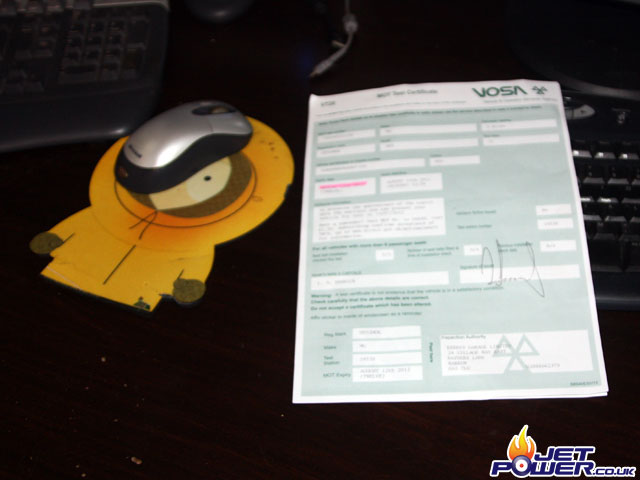

A nervous time, it’s time to go and try and get an MOT. As I am not allowed to take the car on the road it will have to be trailered and as it’s not exactly a trip down to the shops to get this done I have called in a favour from my mate Rick. Rick has kindly offered (after being bought a pint) to tow the trailer to the testing station for me with his Landy.

The MOT test was carried out by a fellow gas turbine collector and project builder Lee Dennick, fortunately all went well and after a couple of rear light bulbs were replaced an MOT certificate was produced – Thanks Lee!

Fanfare please! Obtaining this UK Tax Disc means that I can now legally drive the car on UK roads. To be fair I was expecting the re-classing of the vehicle to be a bit of a nightmare, but was guided by a very helpful lady at the DVLA office. She did mention that the DVLA legal team may or may not yet intervene, but I believe the signs are good. This is ultimately the result I wanted.

And this is the result I didn’t want!

Sh1t happens apparently. During the first road drive the Differential seized leaving me stuck on the side of the road. To add insult to injury, the offside drive shaft had to be cut to allow the car to be towed home. On closer inspection of the Differential after a strip down it became apparent that it had no oil and to be fair was probably in a failing state when it was purchased from ebay about two years ago, a lesson learnt I think.

Fortunately I had a spare Differential ready to be fitted that has come from the Mazda Eunos Electric Car that I am currently making, the downside being that it has a flange type fitting rather than the shaft type that the failed Differential used. So time to make more drive shafts. A pair of MGF shafts arrived quickly that were ordered form eBay and are perfect for the adaption, the MX5 Diff shafts arrived and are wrong. The shaft flanges have a PCD of 70mm, where the Diff has a flange PCD of 80mm, more money wasted. I’m feeling a little down, especially as my day to day car has also just broken down, I currently own three cars and none of them work at the moment. Thankfully my mates at SMD will weld the shafts as a favor, this takes the pressure of me a little bit.

Whilst the Diff and Drive Shafts were being made, it became an opportunity to have a tidy up of the wiring and make some modifications to the control box. I have also modified the way the engine starts and have taken away some of the control that the computer had over the engine due to ongoing corrupt USB data signals which were causing time delays and random actions.

As an additional safety modification I have added a vacuum switch under the bonnet that will flag a warning in he cab should the brake vacuum level fall below a set threshold, probably the most important warning out of them all.

After the sucsessful road test’s that we had at the weekend it was now time to look at at ways of improving performance and efficiency, the main thing that can be done is to reduce the EGT. The engine running with zero load was producing an EGT of around 350DegC with the boot lid closed, with the engine running and the boot lid open it went down to 310DegC. Just as we have always suspected, we need more ventilation in to the engine compartment,. This has now been achieved by cutting two holes in to the boot lid where the metal is only one layer thick.

Vents covered in gold coloured wire mesh and using PU bonded in place.

Soft/ hard top retaining bracket.

Painted and fitted in to place.

Paul testing the charge / speed controller for the GT MGF.

This video shows the lower right motor running on 12 volts alone.

Paul testing the electronic speed controller with the motors and 300v battery packs.

The master doing even more testing.

Testing the motor drive train. My mate Will holding some crocodile clips on to a 24volt battery which is coupled to two of the motors which are wired in series whilst having a test tootle drive.

Smoke machine gas flow test.

Pressure gas flow test.

Testing the speed controller on batteries alone, we also used this occasion to decide on the location of the controller and other electronics that will be required.

The first time that the speed controller has been run under load, quite underwelming to watch but very significant in the development of the car. Paul is facing backwards to keep an eye on the voltage and current usage, he is also controlling the F/R and throttle pot, quite a weird feeling for the driver!

Thanks to our local Horse Stud for allowing us to use their private drive, this was a life saver as we could run the car at proper speeds and still be legal. 40mph was reached and it’s worth noting that this was under battery power only, the GT has still yet to be wired in.