A ride-on Military Drone Kart.

Belgium Military Drone, Epervier D-27 (Jeremy?), unpacked from it’s quite lovely transport case.

Lid off time, so excited, I’m so chuffed. The tail fin, wings etc are attached to the inside of the lid for safe transport.

The vertical tail assembly, the rudder servo is built in to the section with the electrical connections at the base, three antenna connections are just visible to the front.

Out of the transport case and tail fin attached.

Wings removed from the lid of the case.

Wing stabilisers removed from the lid of the case.

D-27, ‘Drone number 27’, only 49 of these drones were ever made as per this useful reference on the Internet.

Business end of the drone, the Lucas CT3201 gas turbine engine , the turbine wheel bears a resemblance to the turbine wheel from the lucas CR201.

Air impingement connection, located on the trailing edge of the starboard wing.

A view of the air impingement internal pipe work.

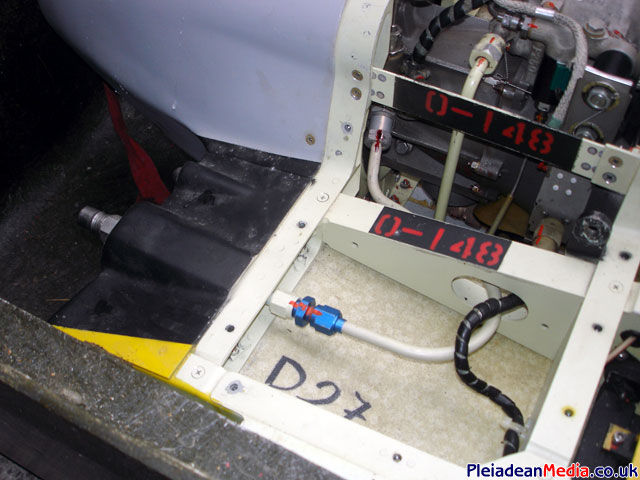

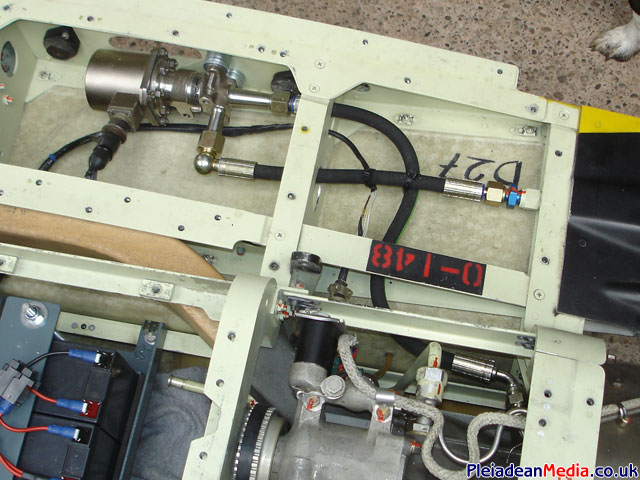

On the Epervier, the Ignitor Exciter is not actually mounted on the aircraft but is part of the ground running and control system, here the external HT connection can be seen.

The outer air duct if for the engine and the smaller opening to the right is for airframe cooling.

Parachute compartment; unfortunately the parachute was missing when I bought the drone, not that I will really be needing it.

Control box mounted under the nose of the drone, I have to mention that this is very heavy and I presume this is where the giro’s are housed.

Parachute canopy now removed, along with the starboard air intake duct.

Fibre glass internal air duct guide removed.

A naked airframe.

Fuel tank removed, bttom view, I presume the flexible fixture at the bottom is for expansion.

No wonder the whole thing is so heavy, mounted on the nose is a substantial amount of lead for ballast, there’s no need for me to keep this on.

Parachute canopy release mechanism removed.

Control assembly for the release mechanism.

Wiring loom carefully removed and for reference, re-connected up, just in case it ever goes back together again.

When the project is completed, I would like to have control of the rudder and elevons, this means working out the wiring, not an easy task at all, so in the rudders case, which happens to have open access to the servo control unit, I have rewired it so that a DPDT switch allows me to move the rudder to compensate for side winds when moving.

Everybody has to look stupid at some time.

This will be my stance when completed, probably.

Undercarriage is the next job, here I’m testing for wheel position and height.

I am trying not to cut in to the drone to much, so I’m am making as much use of the skin retaining screws as possible. The places that I have chosen for fixing are part of the main structure, so should be plenty strong enough.

Port side undercarriage completed (apart from the brakes), also needs a coat of paint.

Mini Moto brake calipers added and frames painted.

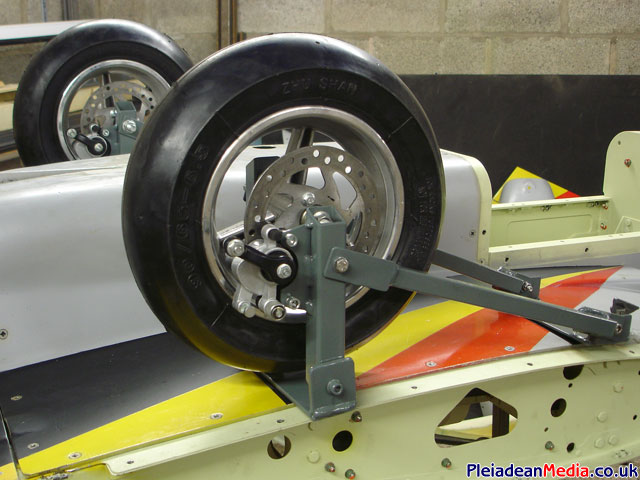

Rear undercarriage completed. Now for the front.

Start of the front wheel assembly, this will form the best part of the front supporting structure.

Lower wheel support frame.

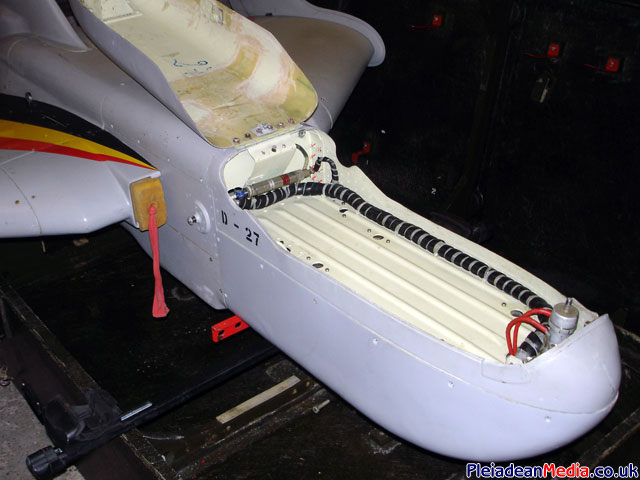

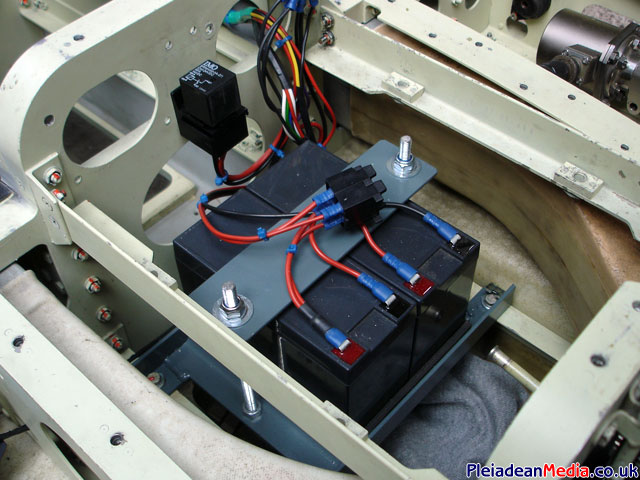

Battery Compartment and Battery’s added. As the Lucas turbine is an air start unit, I can safely get away with using low current battery’s, plenty of power for the control panel and other systems.

The air impingement pipe is now routed via a HP air valve, which is controlled from the control panel.

Aluminum control panel added. EGT Gauge, RPM Gauge, Air Start & Igniter Push Button, Master On/Off switch and HP Cock.

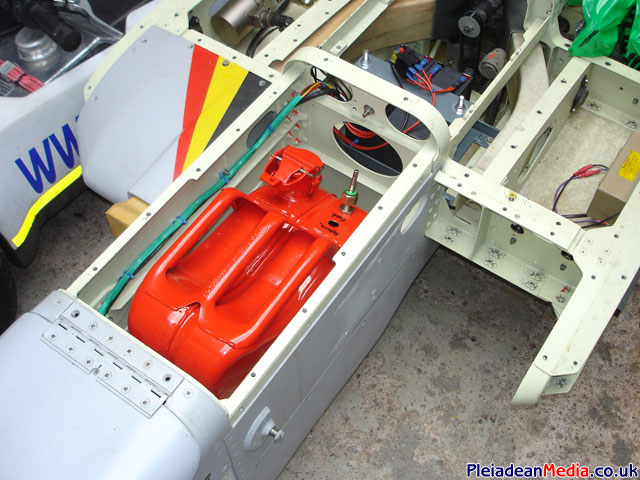

As I seem to have taken on too many projects and my girlfriend is complaining about all the money i’m spending, I have made the decision to go for a basic and cheep fuel tank in the from of a 2 gallon jerry can. This fits nicely in to the camera compartment of the drone. A fuel feed and return system have been utilised using 1/4 bsp hydraulic fittings.

Today I had the first test run of the engine. It didn’t go smoothly at first due to the fact I hadn’t bled the fuel system properly and the initial air starting pressure was low.

A sign that someone with a jet engine lives at this house. All jet enthusiasts get this, usually along with a ear full from the better half.

Drone foot rests fitted and front side panels, I decided not to touch the original nose panel, so that at any time it could be converted back to its original state.

1 x padded seat.

Some Logo’s.

A micro switch added to the original brake lever will act as a throttle for the engine, idle or high power.

And then like most of the things I make, it was sold to help fund the next project. Lee Dennick took it on and made a new control panel and gave it a very worthy paint job, looks absolutely fabulous.

Kerosene Junkie, Lee’s nickname.