This is going to be the largest and most time consuming project I have ever undertaken. Lots of bits missing that will need to be sourced or made, this is going to cost me..

I hope the wife doesn’t find out!

The Rolls Royce / Snecma Olympus 593 was the engine fitted to the Concorde, four engines allowed Concorde to travel at speeds in excess of Mach2, (1522 MPH).

The engine is located at Bruntingthorpe Airfield, along with a rather large selection of cold war jets which mainly belong to the Walton family. The front of the Olympus 593 viewed in the foreground with a Blackburn Buccaneer, registration XX900 in the background.

On it’s 100 mile trip to its new home in North Shropshire from it’s home of the last few years.

When transporting engines about I always try to use ‘Shebdons of Telford’, they cant be more helpful and understand the complexities of moving aero engines about.

The Olympus weights in at about at just under 3 1/2 tons, plus a bit more with the transport frame, thus a heavy duty crane is required to do the job.

A happy, but somewhat nervous smile as the realisation of the project I have just undertaken hits me!

Temporarily on blocks, a quick check over and the planning starts.

The compressor is in remarkably good condition considering the amount of time it spent outside, also there is evidence of some blending on the compressor blades, so it has clearly been overhauled at some point.

A nice picture of the first stage of the compressor.

Now if that isn’t beautiful I don’t know what is!

My son Freddie giving a bit of perspective to the size of this engine.

The engine generally seems to be in good condition, although that remains to be seen, standing outside for a number of years with exposed pipework maybe be a show stopper. The tatty transport frame doesn’t help the aesthetics of the Olympus 593, at some point a sand down and a coat of paint will help sort that.

The afterburner pipework and gutters are fitted to the Olympus 593 which is unusual as the afterburner hardware is normally part of the jet pipe (which unfortunately I don’t have and is consequently not part of this project).

The vapor gutters of the afterburner and the thermocouples of the engine can be seen in this photo.

Engineers markings on the final turbine section, it has to be said, compared to other engines that I have worked on these blades are long.

Combustion and turbine section heat shields which will help protect the airframe from radiated heat produced by the Olympus.

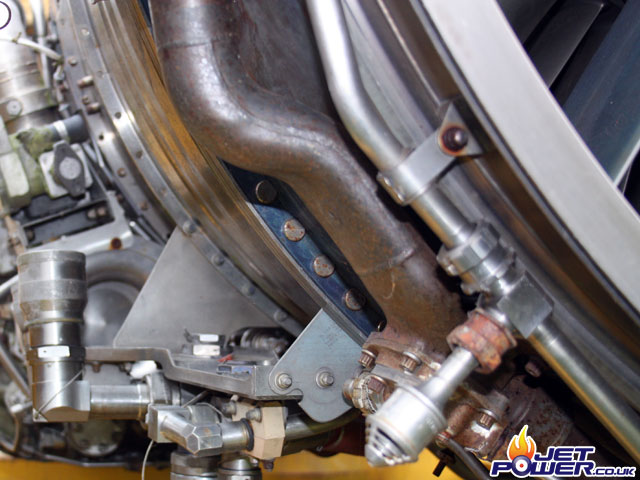

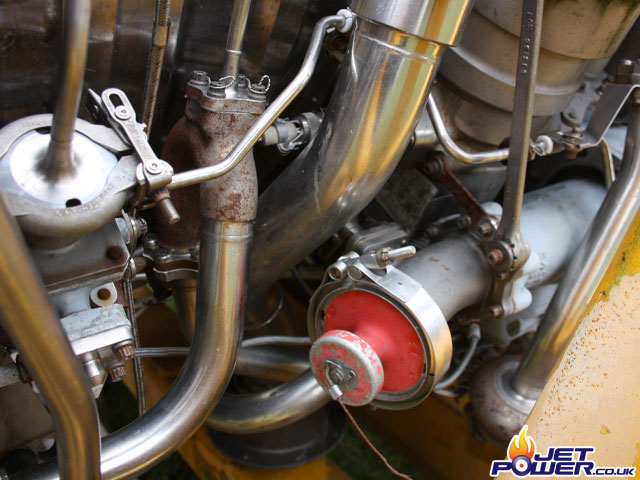

Just out of focus in the foreground mounted around the compressor housing is a fire suppression ring, one of the distribution nozzles can be seen bottom right.

Hydraulic pipework on the underside of the Olympus, although part of the engine, I am going to remove the assembly as it is not required for running and its just going to get in the way.

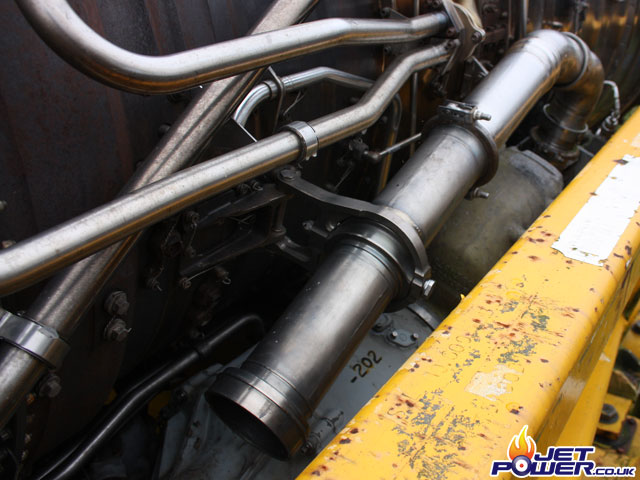

Pneumatic (Turbo) Starter feed pipework, the air delivery APU used for starting the Olympus will have to interface with this pipe.

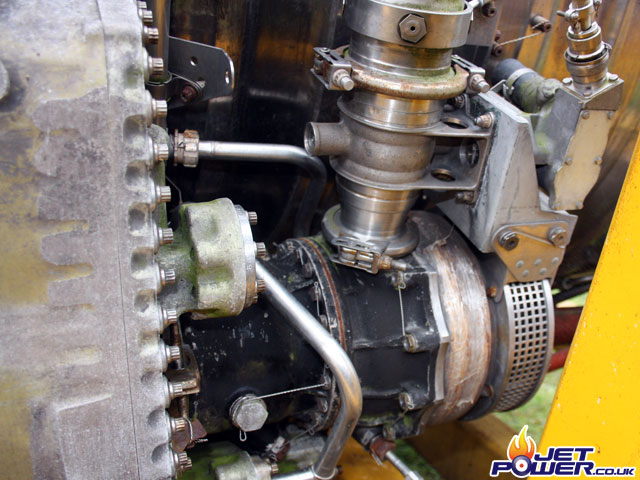

Pneumatic starter, needs a good clean.. Air delivery feed is at the top and is exhausted from the perforated gill at its circumference.

The mechanism on the top is the delivery air on/ off valve, which is electrically actuated.

A rear view of the pneumatic turbo starter with the air delivery mounted on the top.

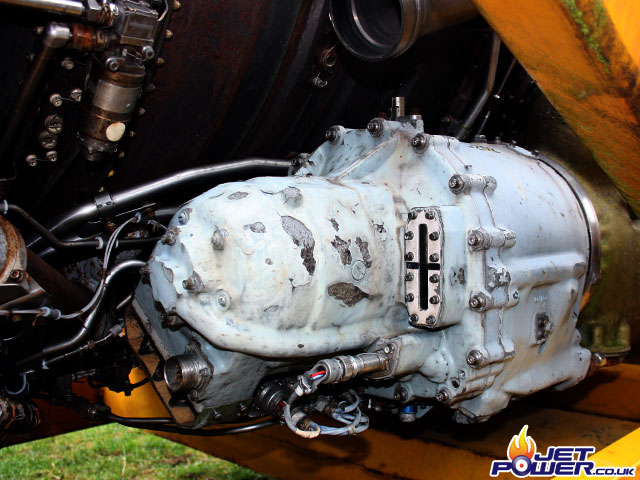

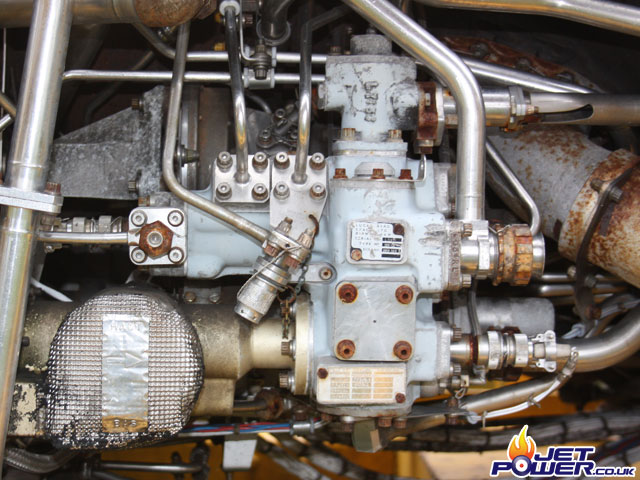

This lump is the CSDU or Constant Speed Drive Unit and 400Hz Alternator. The paints peeling of and looks rather rough unfortunately, but it is all there and looks aren’t everything so I’ve been told. Another item that will need a coat of paint.

Fuel inlet port for the Olympus, currently blanked off.

Oil reservoir tank, this occupies almost all of the front port side of the engine, well maybe not but it is a large tank.

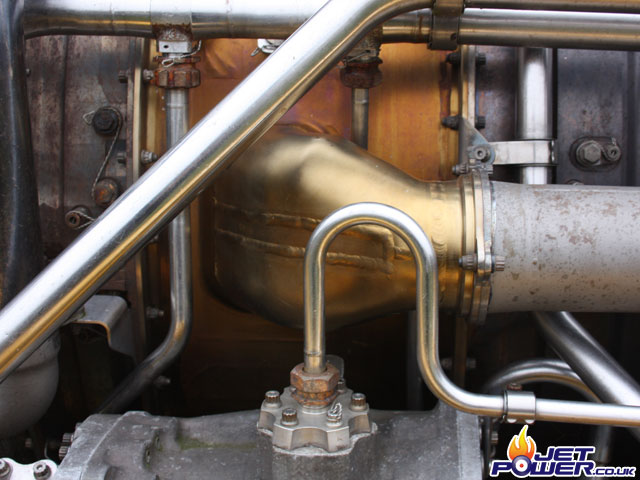

Nice and shiny / beautifully made air bypass pipework from the compressor.

Part of the Olympus 593 fuel control unit or FCU. The larger pipe that is centre top feed the injectors in the combustion chamber.

Electrical connections for the Olympus, I tried so hard to find some mating connectors for these but with no luck, a plan B will have to be formulated as plan C will be to cut the wires and solder standard connections on instead, this I would rather not do!

Luckily, for support and his extensive knowledge of electronics I get help from my buddie Jon Starr, there’s not a lot he doesn’t know. You do have to occasionally wind the key to keep him going 🙂

The whole transport crate assembly is a bit of a lump and I need to reduce its overall size, so after a bit of tootling the base was removed from under the engine. Quite a mean feat as I don’t have access to a fork lift or tele handler which would make my life a lot easier. Maybe I will do the lottery tonight..

I went to a military auction that was held locally-ish to me and ended up buying this transport trolley, more than capable of supporting the Olympus 593 with some modifications. So now its going to be mobile at least.

And hey presto! Four leg supports that will fit the remaining part of the transport frame. I’ve made the mounts high so that when I save up and buy a lorry the heights will be about the same, it also allows for easier maintenance working under the Olympus when mounted on top of it.