I have decided that I better have a go at making a Gas Turbine form a Lorry Turbo.

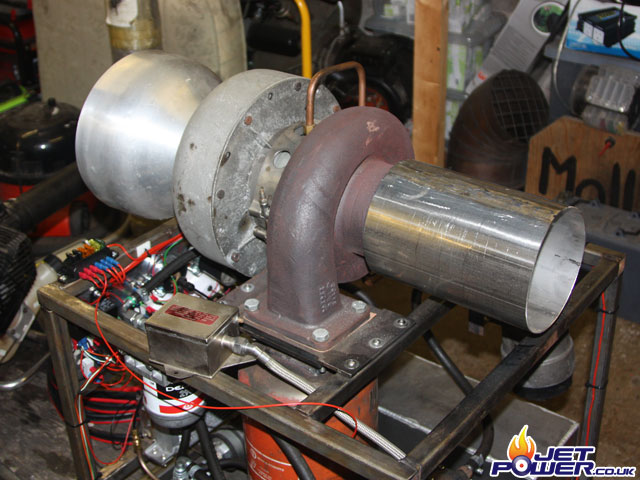

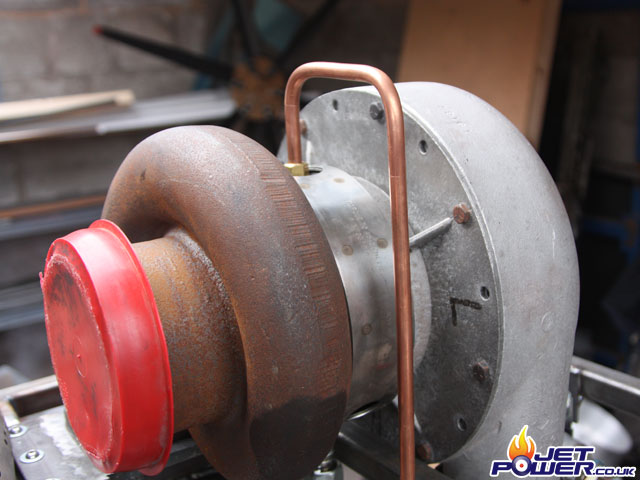

My New Turbo (VT 50) which has come from a 16 Litre Cummins Lorry Engine.

Air Inlet / Compressor Section.

Exhaust / Turbine Section.

The flame tube from a scrap GTP30 and an old fire extinguisher.

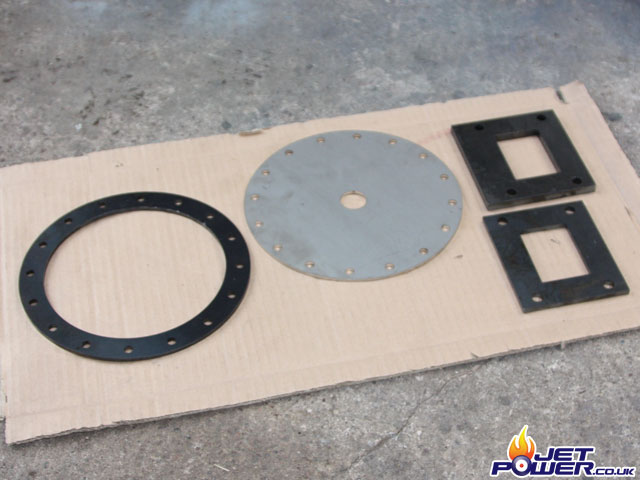

Laser cut items. Combustor lid flange, Combustor Lid, Engine mounting Bracket and the inlet to the turbine section of the turbo.

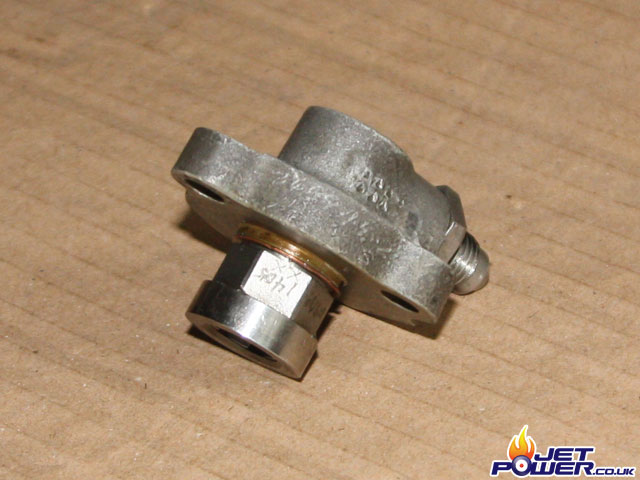

A home made adapter to connect the combustor flange to the combustor tube itself. This has been profiled to the shape of the fire extinguisher.

A GTP30 Injector Nozzle.

Lucas CAV Fuel Filter Assembly.

Bosch 044 performance fuel pump from acar.

My speed controller setup for the fuel pump. Speed Controller, Battery Pack, Servo Speed Reaction Device and A Servo Tester.

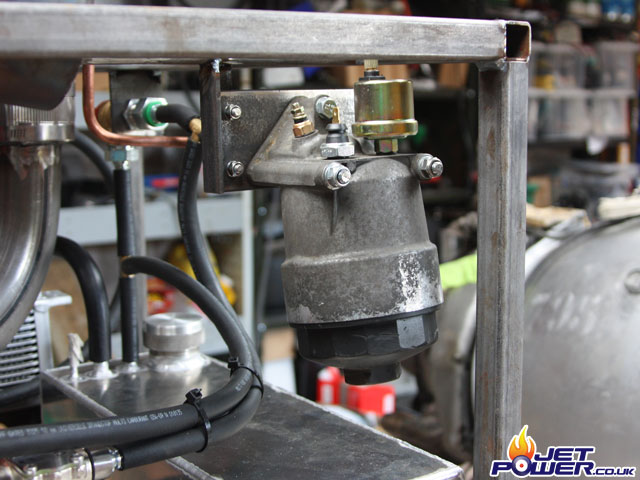

This HP oil pump will provide the 40psi oil pressure required to keep the Turbo running.

Needle valve to regulate the oil pressure to the Turbo.

Oil Cooler Radiator.

Oil Cooler Fan.

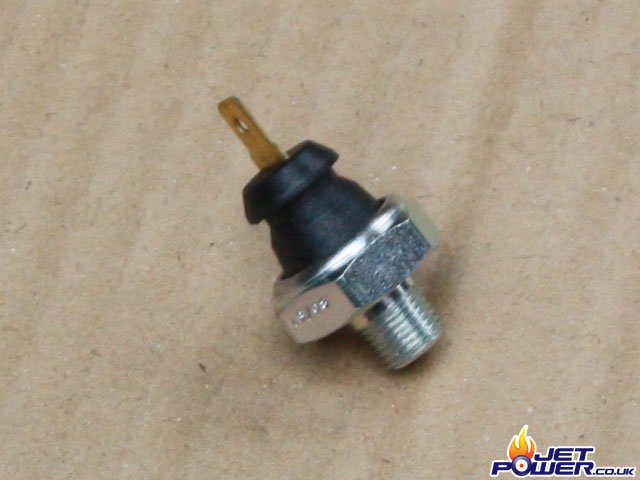

Oil Pressure Switch, as a safety measure, this will be used to only allow the fuel to be turned on if there is oil pressure.

Oil Filter Assembly from a VW, it it designed to fit direct to the original engine, so a fabricated back plate will have to be made, the start of the plate is pictured, I do have concerns whether it will seal correctly, I suppose we shall soon see.

3 Bar Pressure relief valve to regulate the oil supply to the turbo, I have a small concern that the rubber valve may perish with the oil flow, but if it stands up to that then I think it should work a treat.

Cheep Oil Pressure & Oil Temp Gauges & Sensors.

Igniter Exciter Unit & HT Lead.

The start of the combustion chamber.

I found the easiest way of removing the plastic seal inside the tube was by applying a heat source to the outside and then scraping the plastic away with a flat ended screwdriver.

This will form the DIYGT’s Transport Fame.

Transport frame fabricated, with the Turbo support bracket mounted in to place. The mounting plate is spaced 2mm above the frame to help reduce heat transfer from the turbo to the frame.

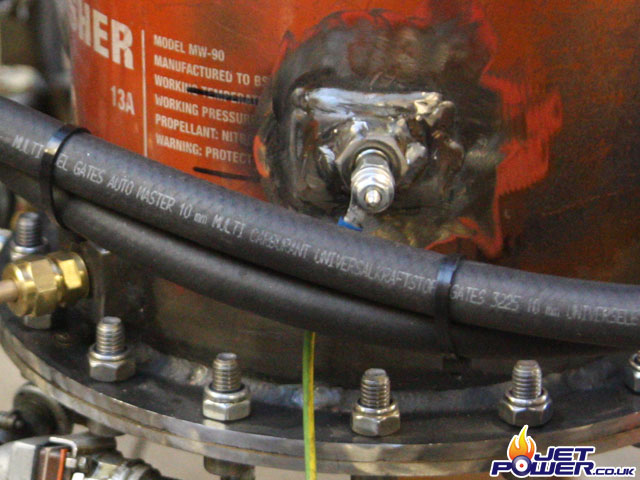

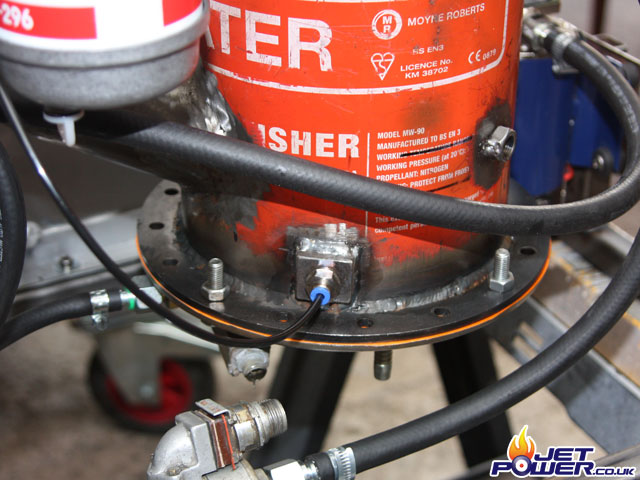

Combustor flange and neck now securely welded on to the combustor. The circular flange has now been cut down a little more and the end flange tack welded in to place. I have also marked out where the air feed will enter the tube.

A quick test to check it all fits ok, so far so good.

I have to say, I was very happy with the tolerance and accurate curve that I managed to get on the pipe that will be attached to the combustor, So It’s a shame that I cut it 90 degree’s from what it should have been. Short attention span, that’s my problem!

Pipe shortened and hole cut in the combustor ready for welding.

The bent part of the pipe has now been reattached to the inlet pipe at the correct angle and then welded to the combustor.

Again, a quick fit just to check that all slots in to place.

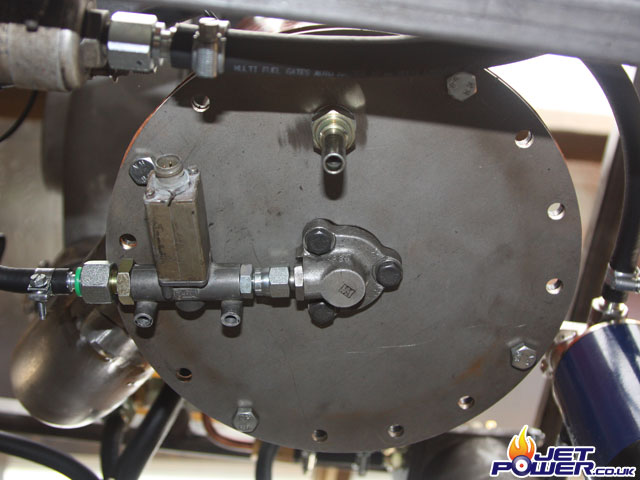

The Oil filter housing has now been bolted on to the back plate, which in turn has been tapped with 1/4″ BSP threads so that two 8mm pipe fittings can be securely attached in to place.

The oil filter has now been mounted on to the frame and the required sensors bolted in to place, a quick pressure test reveals no leaks from the homemade back plate assembly, which is nice.

At the top of the picture you can see that a fuel drain has been fitted in to the flange of the combustion chamber so that any excess fuel can be drained safely away. I have also fitted a NC valve directly on to the injector, this will make sure that the engine will stop at exactly the moment the stop button is pushed.

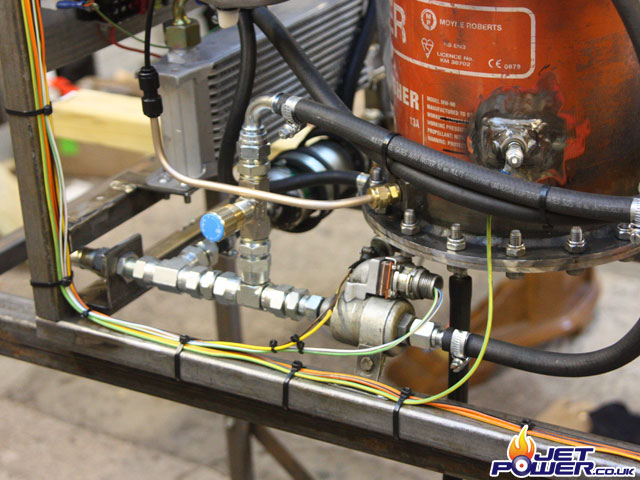

1/2″ high temp hose is used for the oil return path.

3/8 copper pipe and compression fittings are utilised for the oil feed.

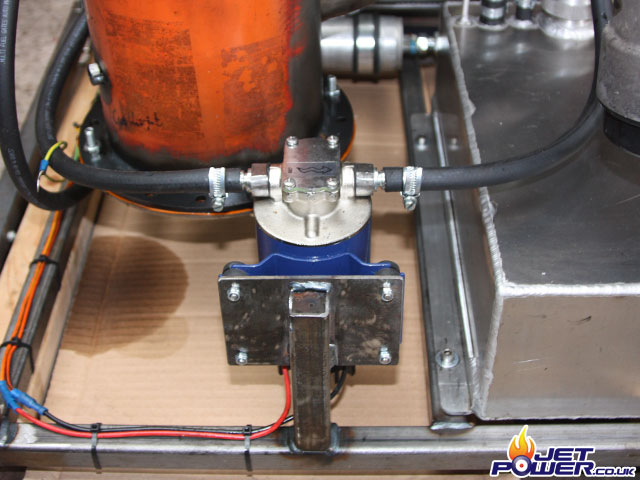

Oil pump mounted and partially plumbed in.

Fuel filter attached and I have also marked the location of the igniter position on the combustor.

An air tap-off has been fitted in to the side of the combustion chamber so that combustor gas pressure can be measured via a gauge that will be mounted in to the control panel.

From the left, 3/8 QR fuel inlet connector, tee to supply fuel to the pump, manual bypass trim valve and lastly a NC fuel shut off valve.

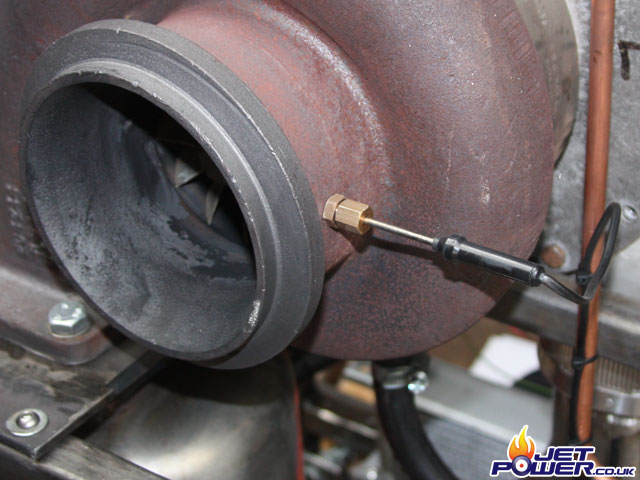

The thermocouple has been held in place by using a 3mm compression fitting, which in turn has been tapped in to a hole in the turbo.

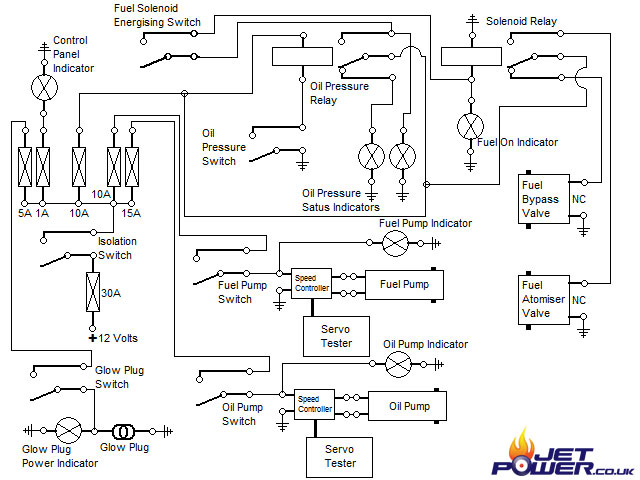

Current wiring diagram, I expect this may change slightly at some point.

Work in progress. Front of the control panel. Nothing like using scratched aluminium.

From the left:- Throttle, RPM, EGT, P2, Oil Pressure, Oil Temp, Oil Pump Switch & Indicator, Glow Plug Switch & Indicator and Fuel Flow Valve Switch & Indicator.

To help improve efficiency I am going to make use of an agricultural aluminium lamp shade, it has all the right curves in the right places. Thanks PD!

Attaching the newly made intake trumpet is going to be a rather crude affair, but it will serve its purpose. At some point I will make use of the bolt holes that are available in the compressor housing.

Unfortunately the housing does foul on the metal frame, so I had no choice but to cut a small slot in the aluminium.

Start of a basic jet pipe, this is definitely going to be a pain as there are no bolt holes to attach any form of pipe to, some drilling of the turbo’s flange will probably have to be done here.